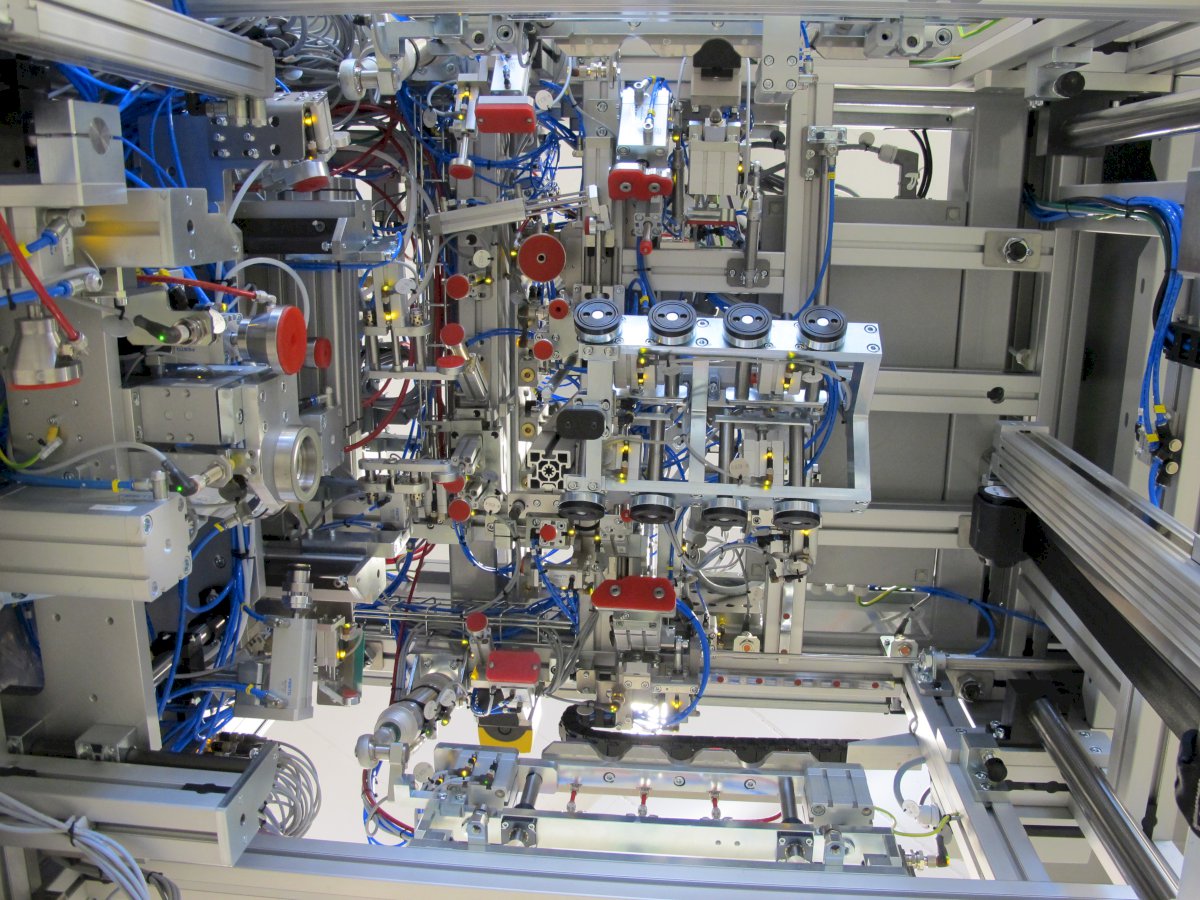

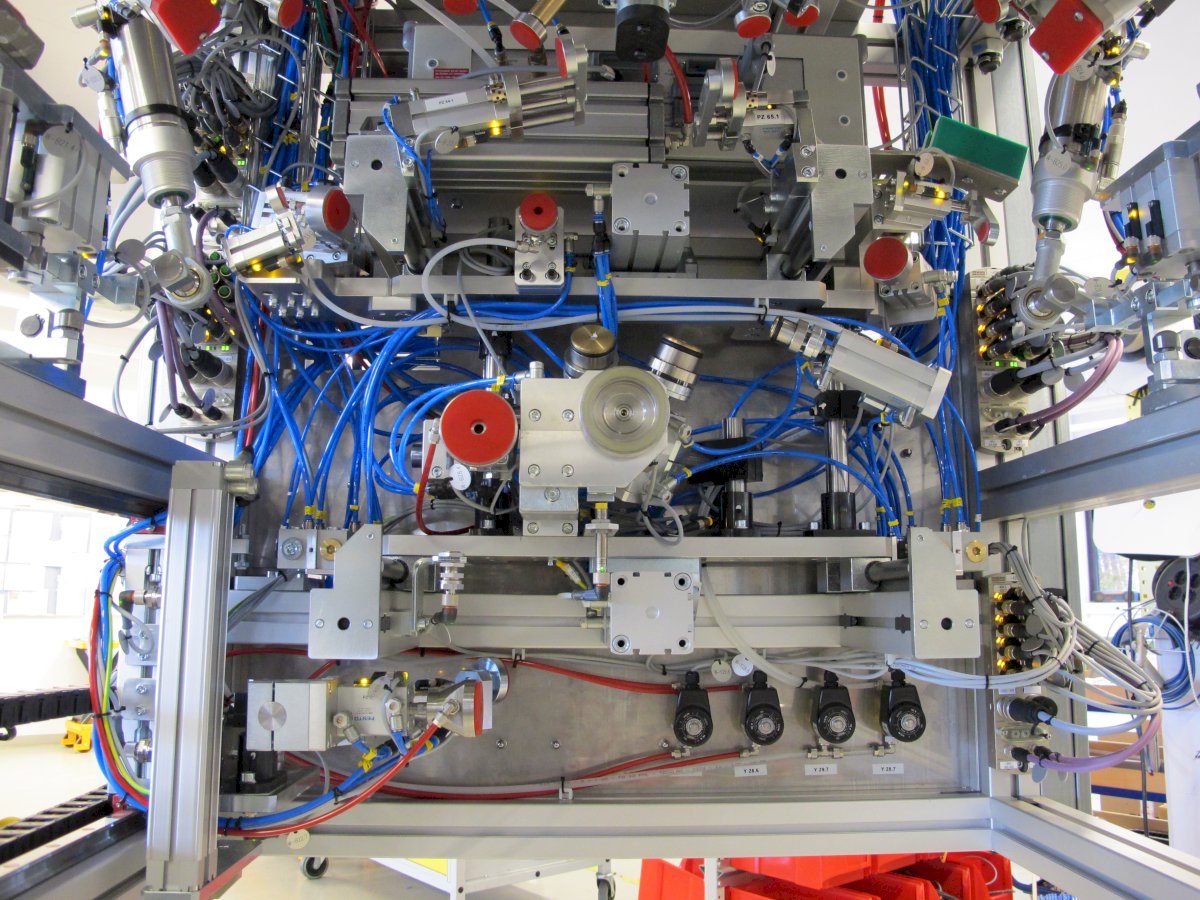

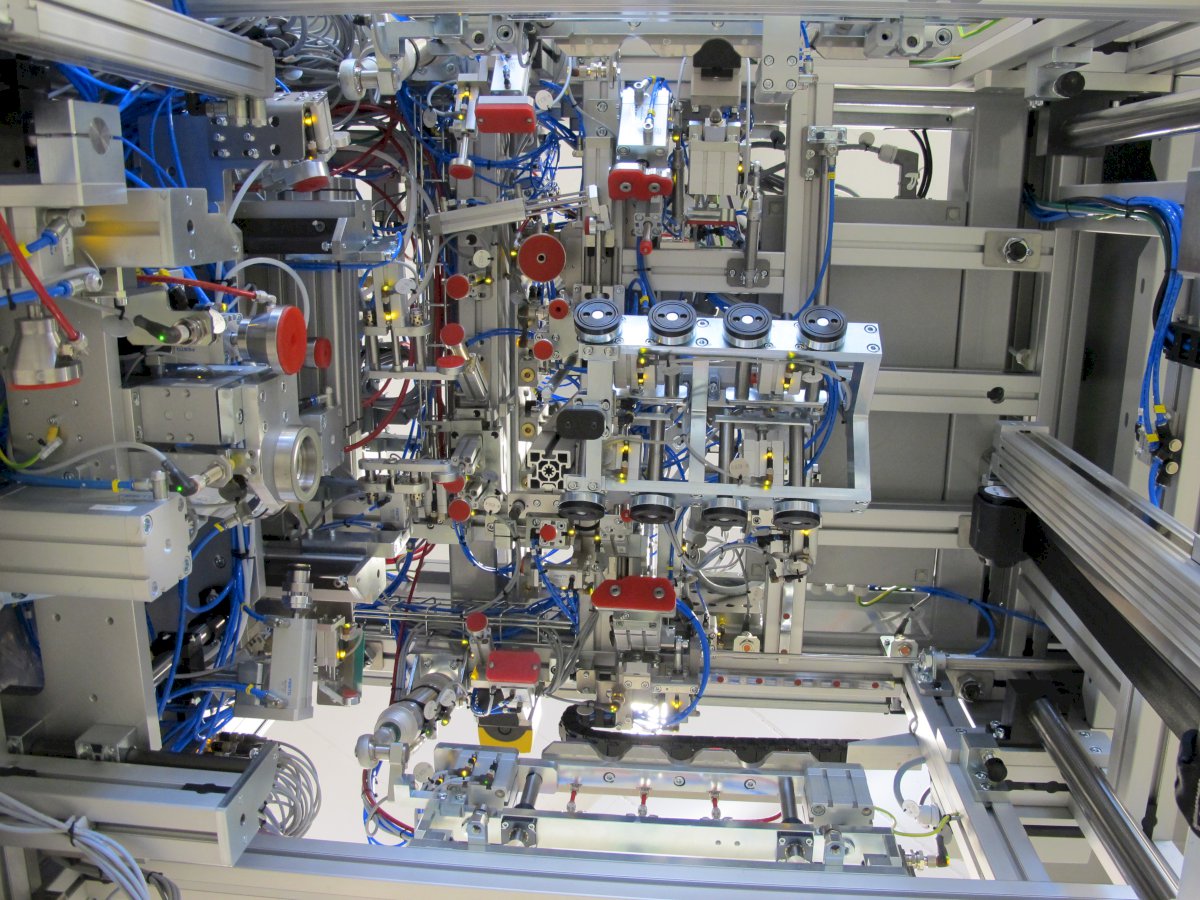

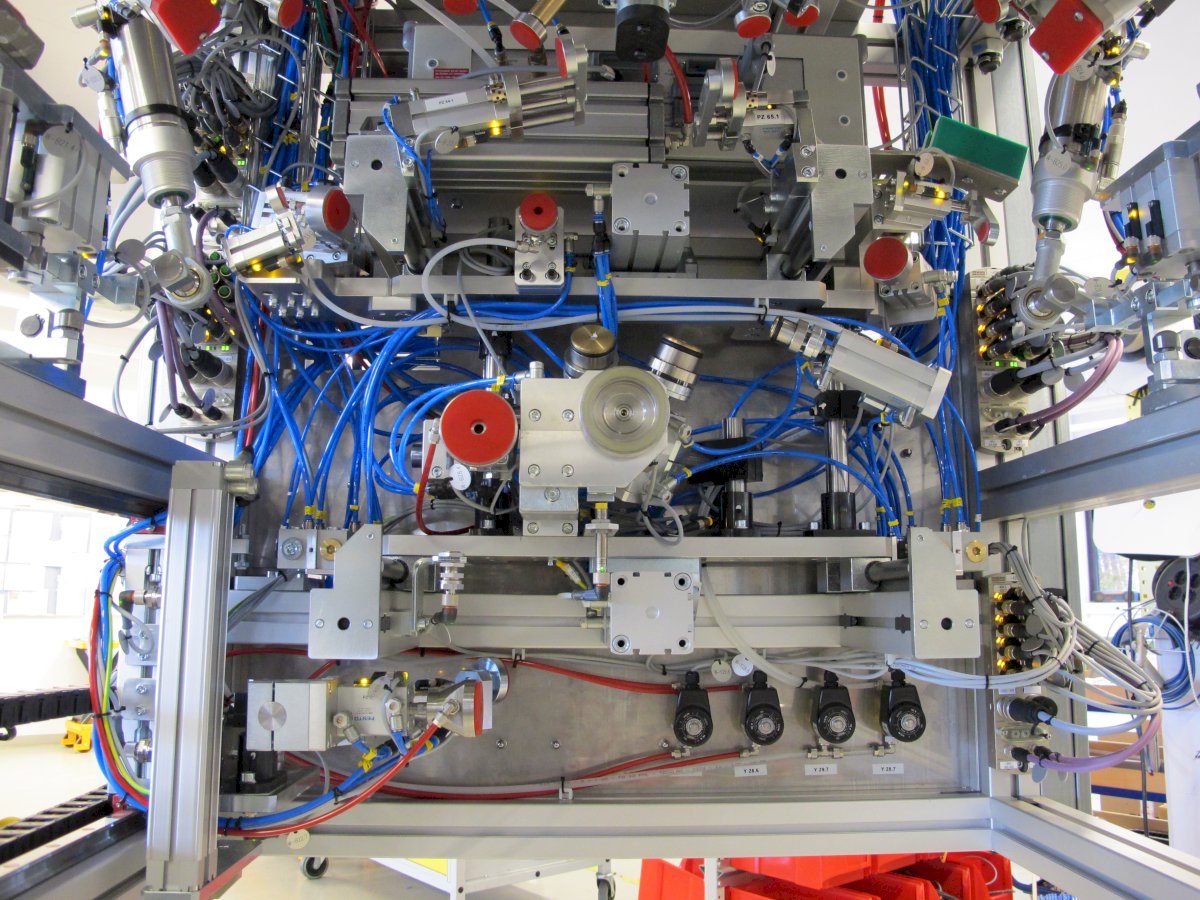

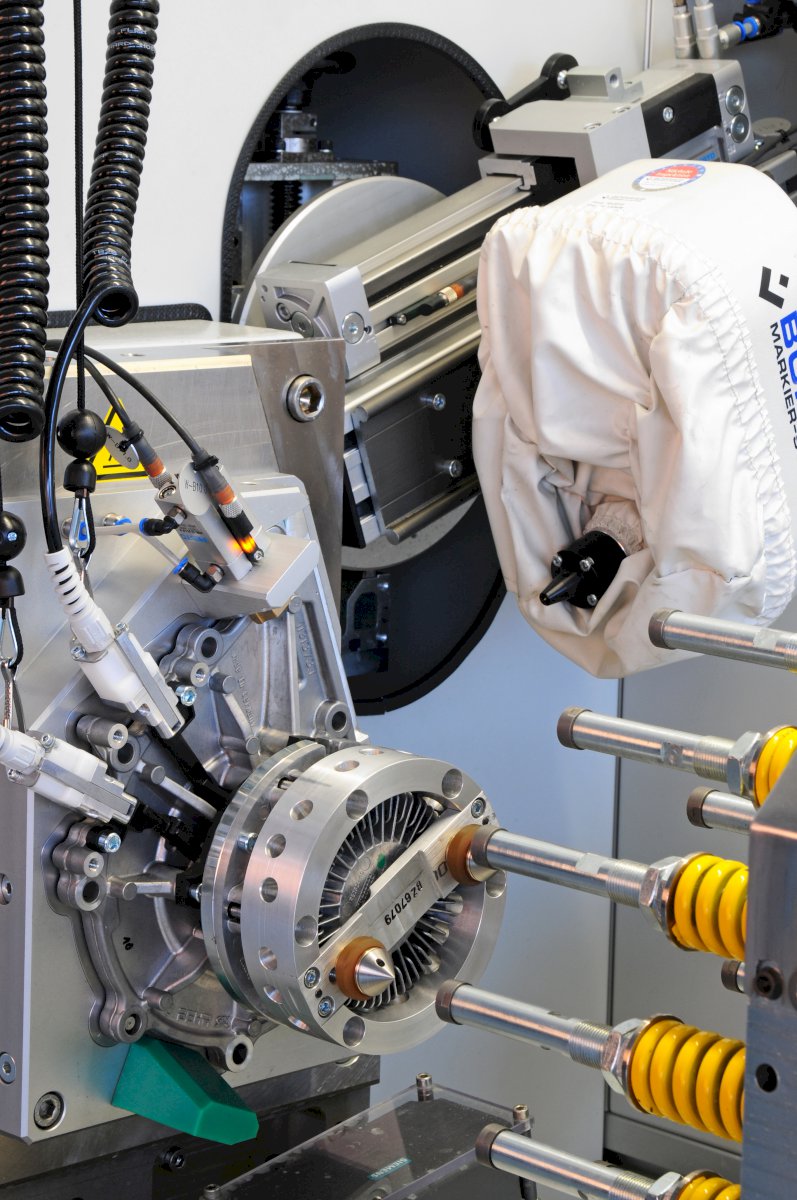

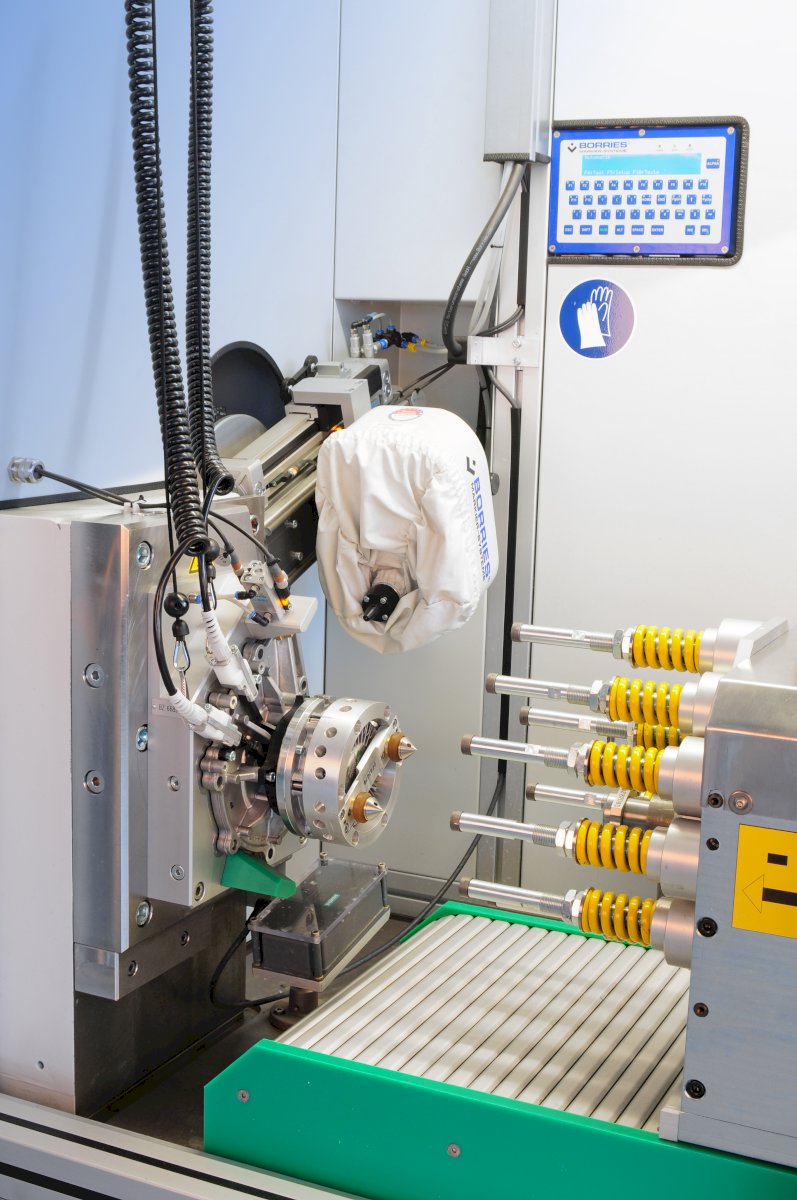

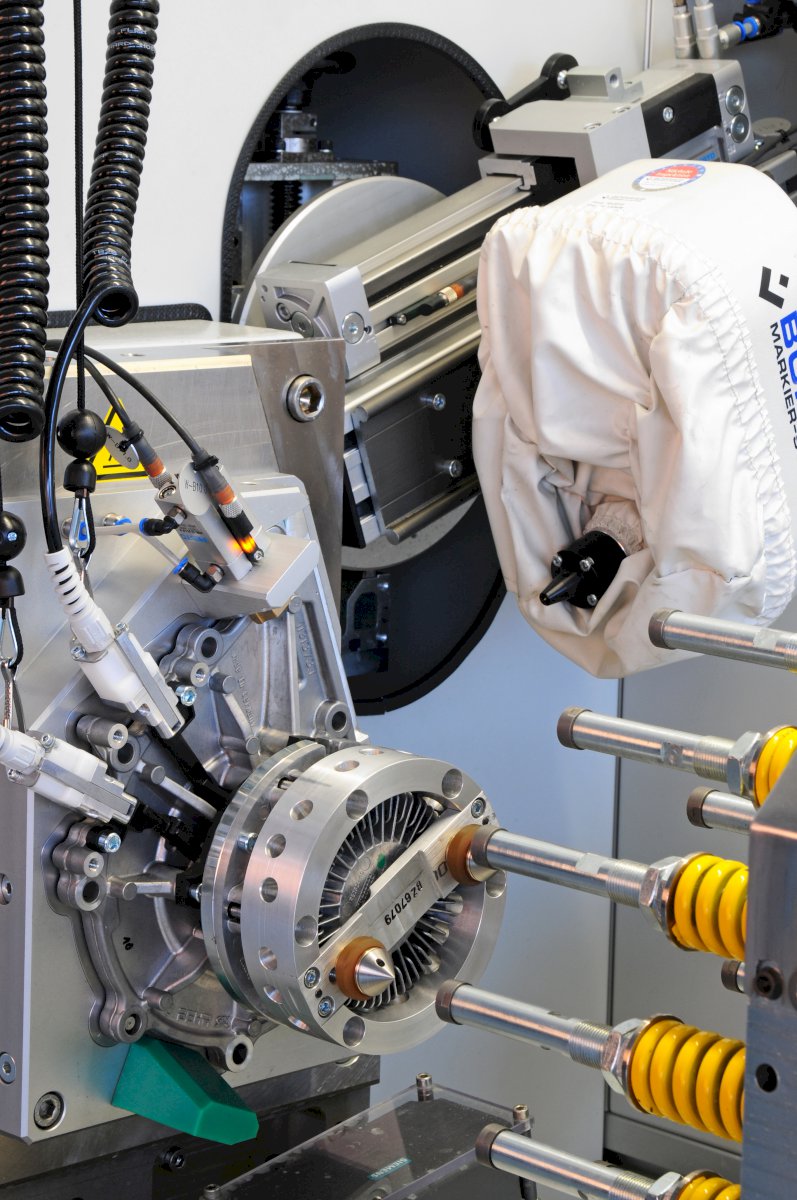

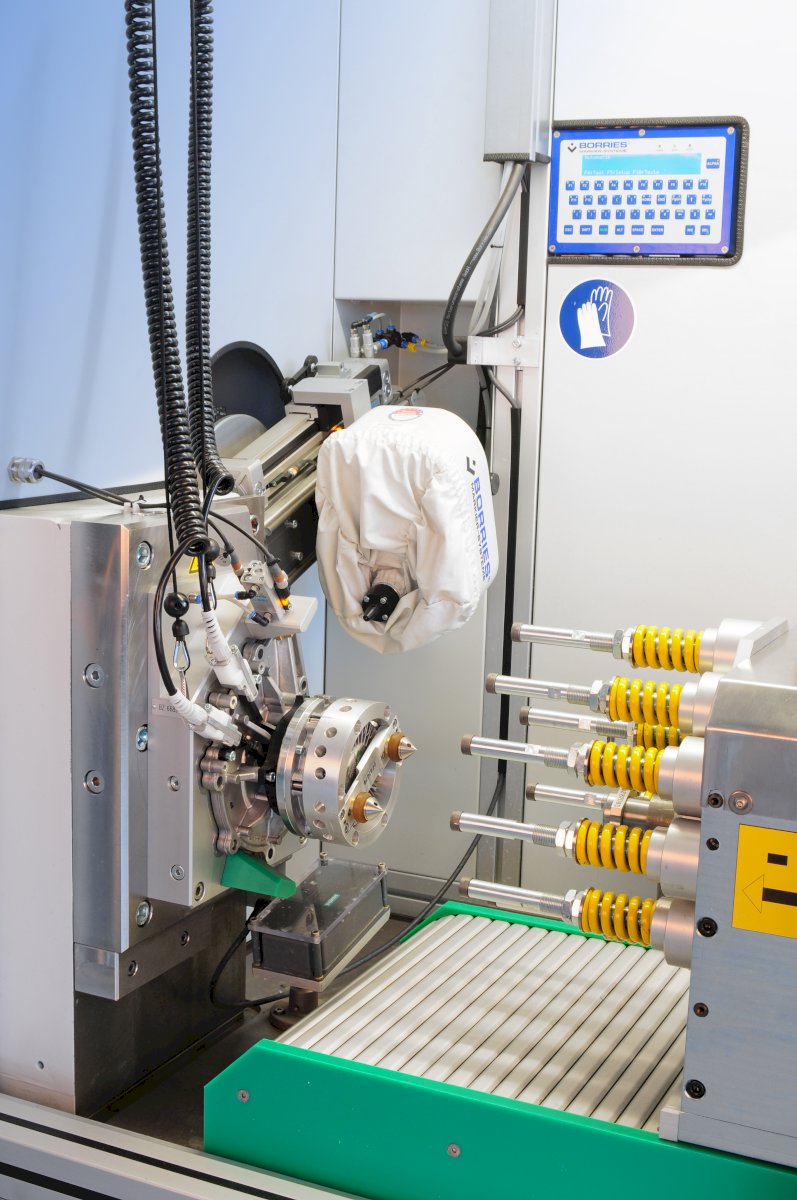

The engines to be tested are inserted into the system on an assembly trolley, before being automatically secured and indexed. The following values are then recorded and measured in an automatic sequence:

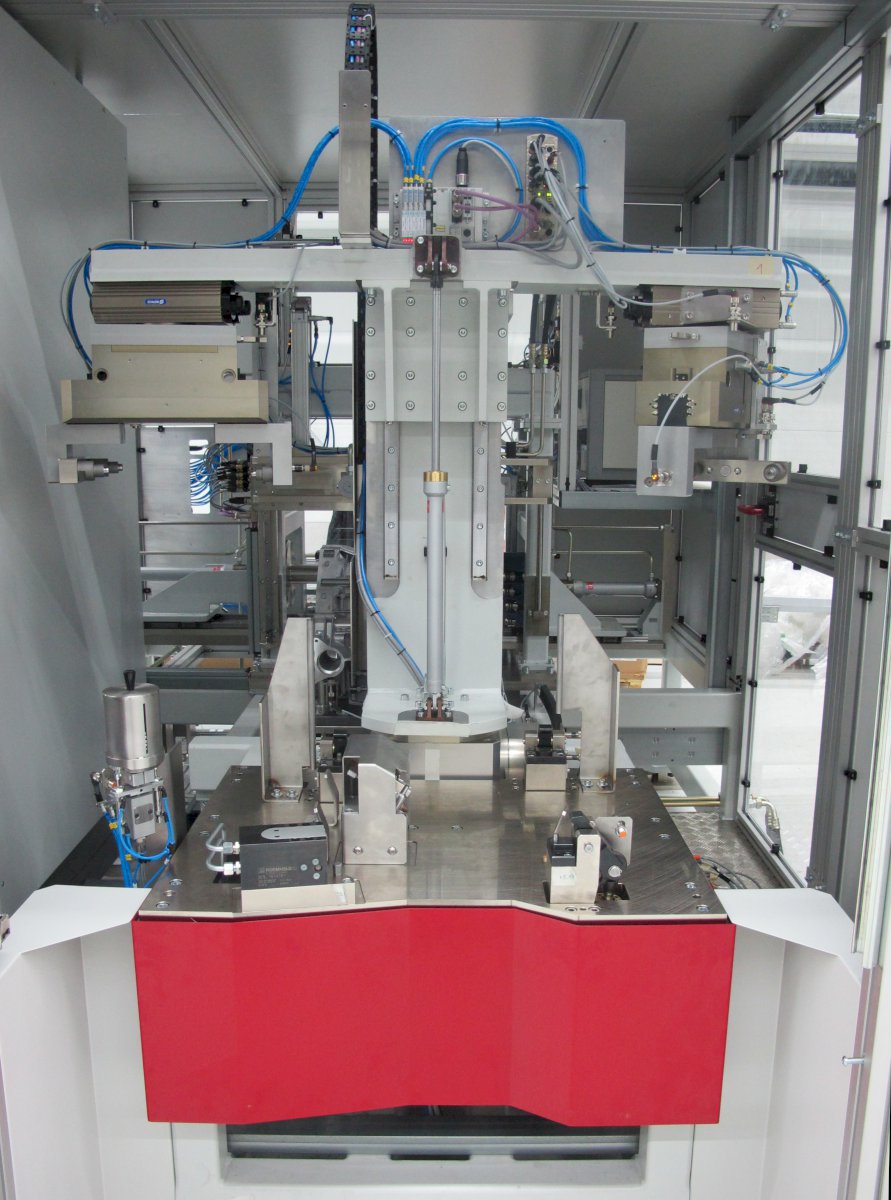

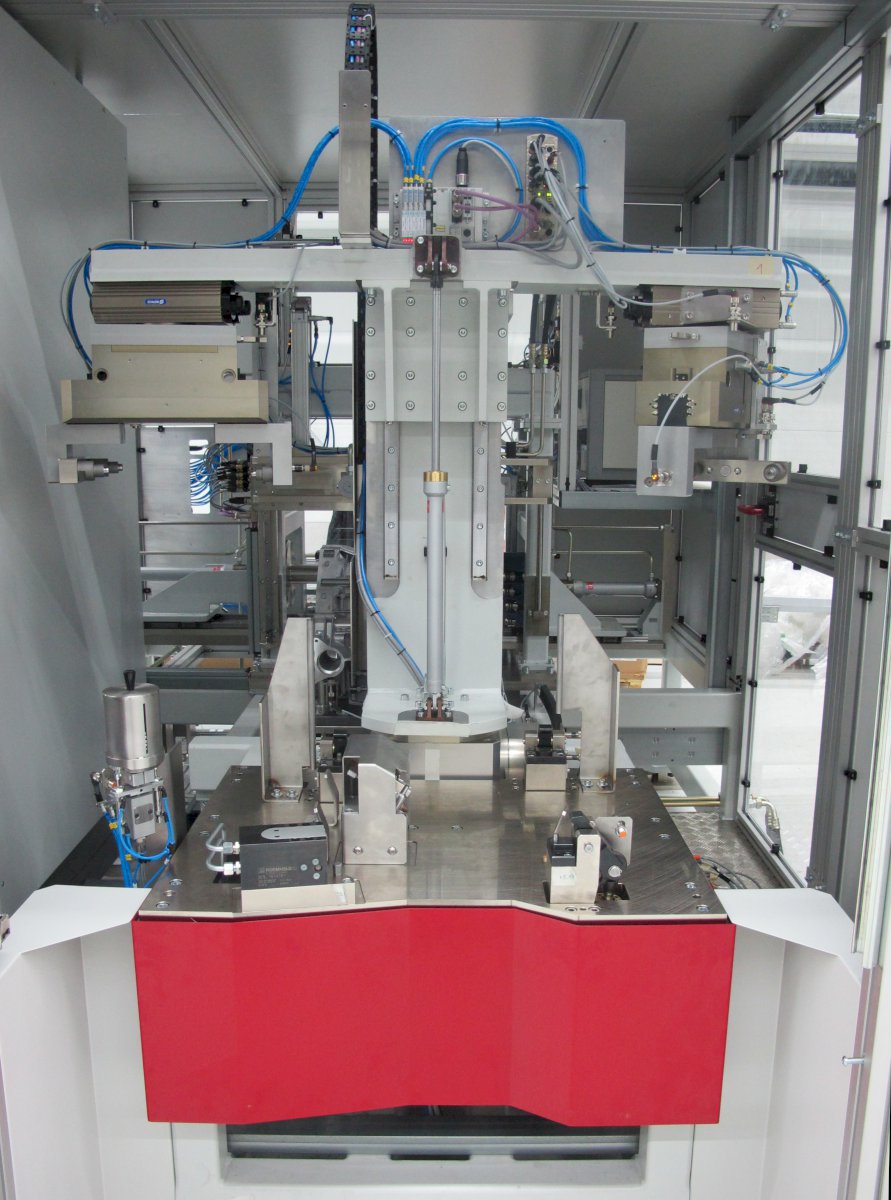

The leak testing system is mounted suspended from a KBK rail, and is lowered down onto the assembly trolley via a two-hand control. It is adapted and indexed automatically before the following leak tests are carried out:

The test specimen is inserted into the ball insertion station via a gantry loader.

A ball is pressed into the test specimen.

The test specimen is then placed on the carriage and inserted into the leak testing system.

The specimen is then tested for leaks.