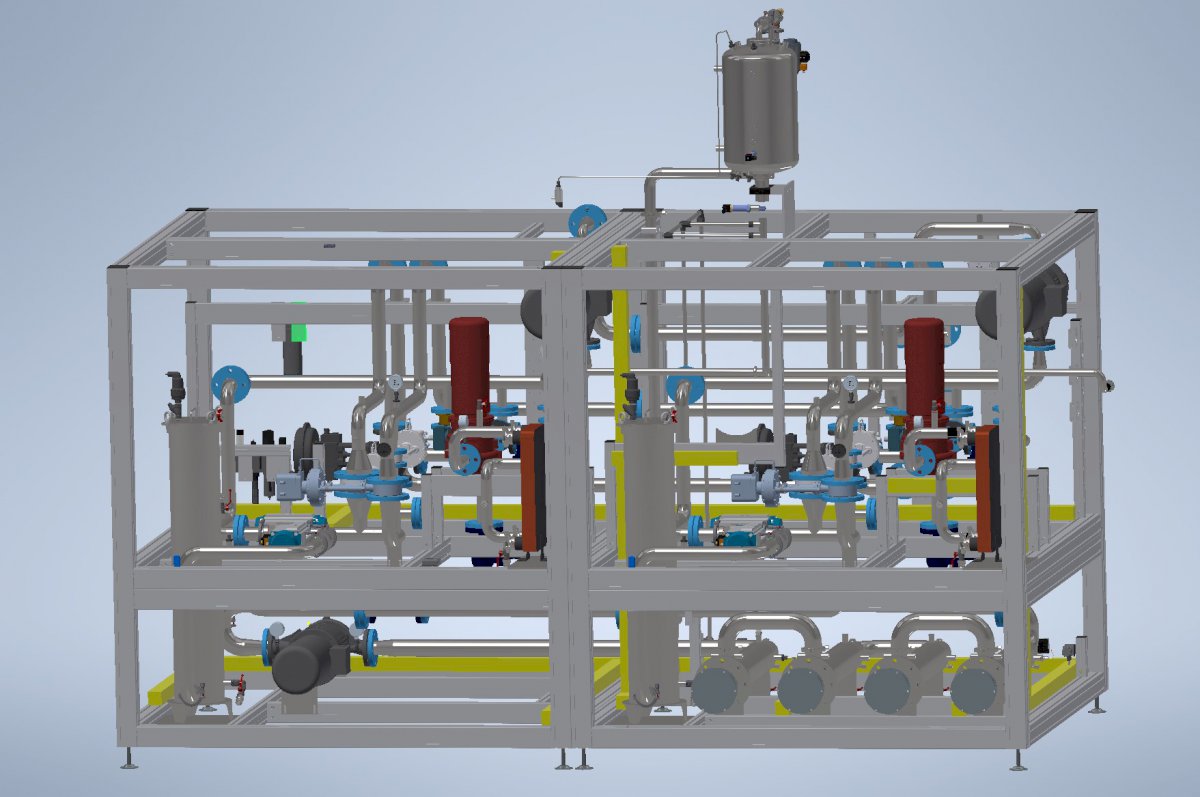

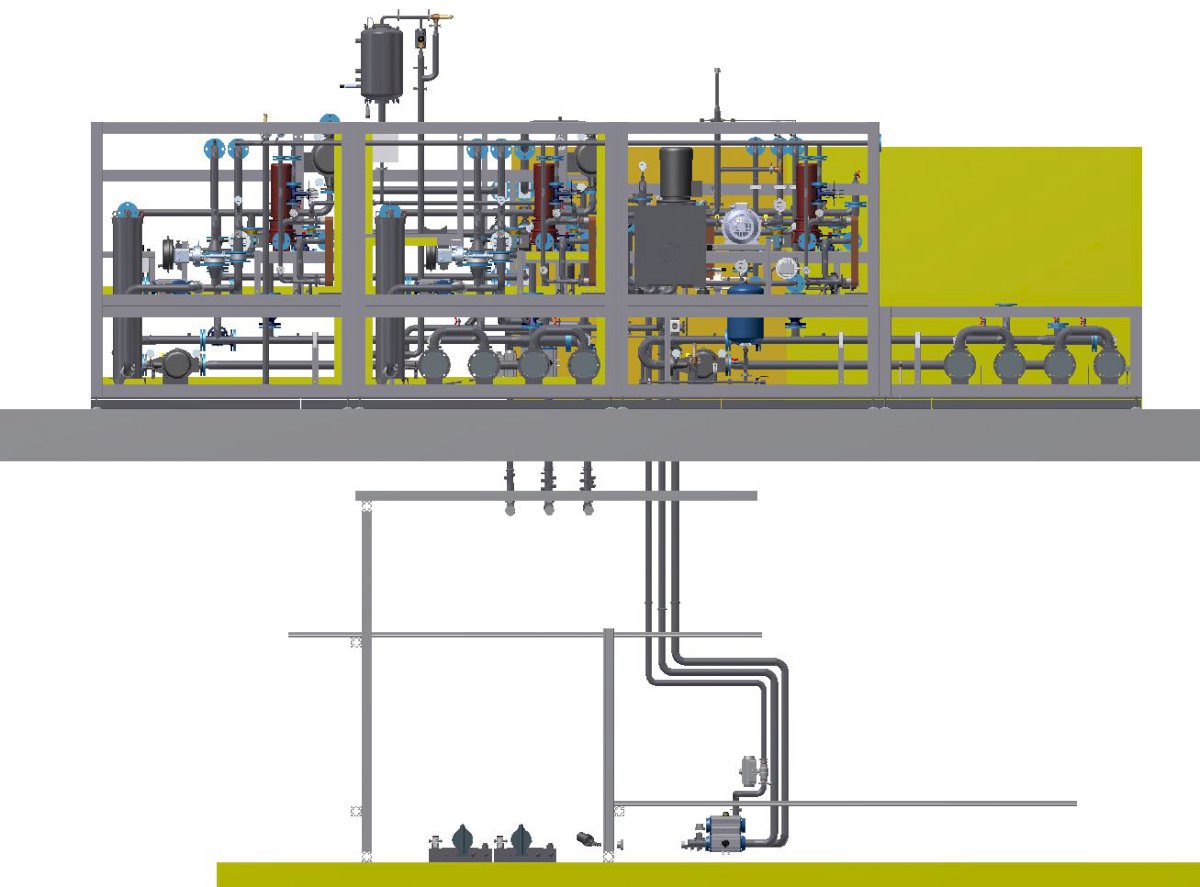

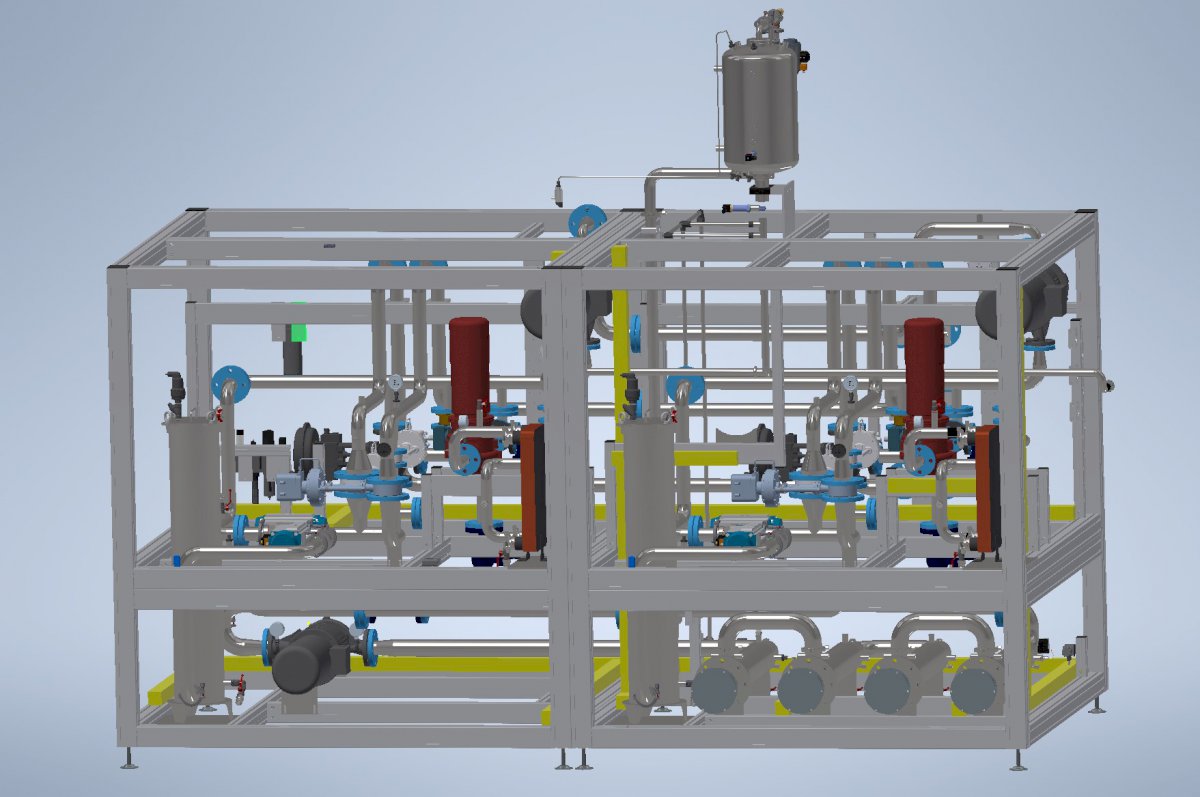

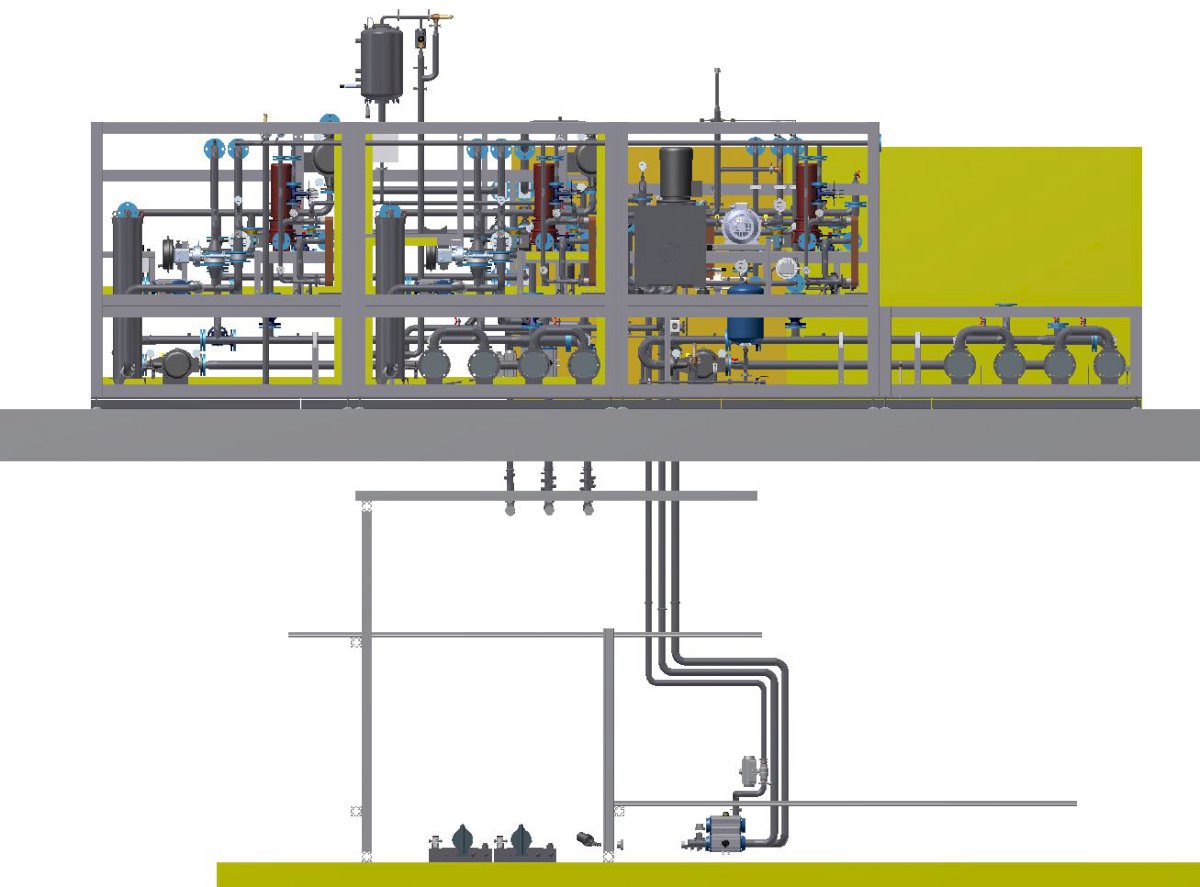

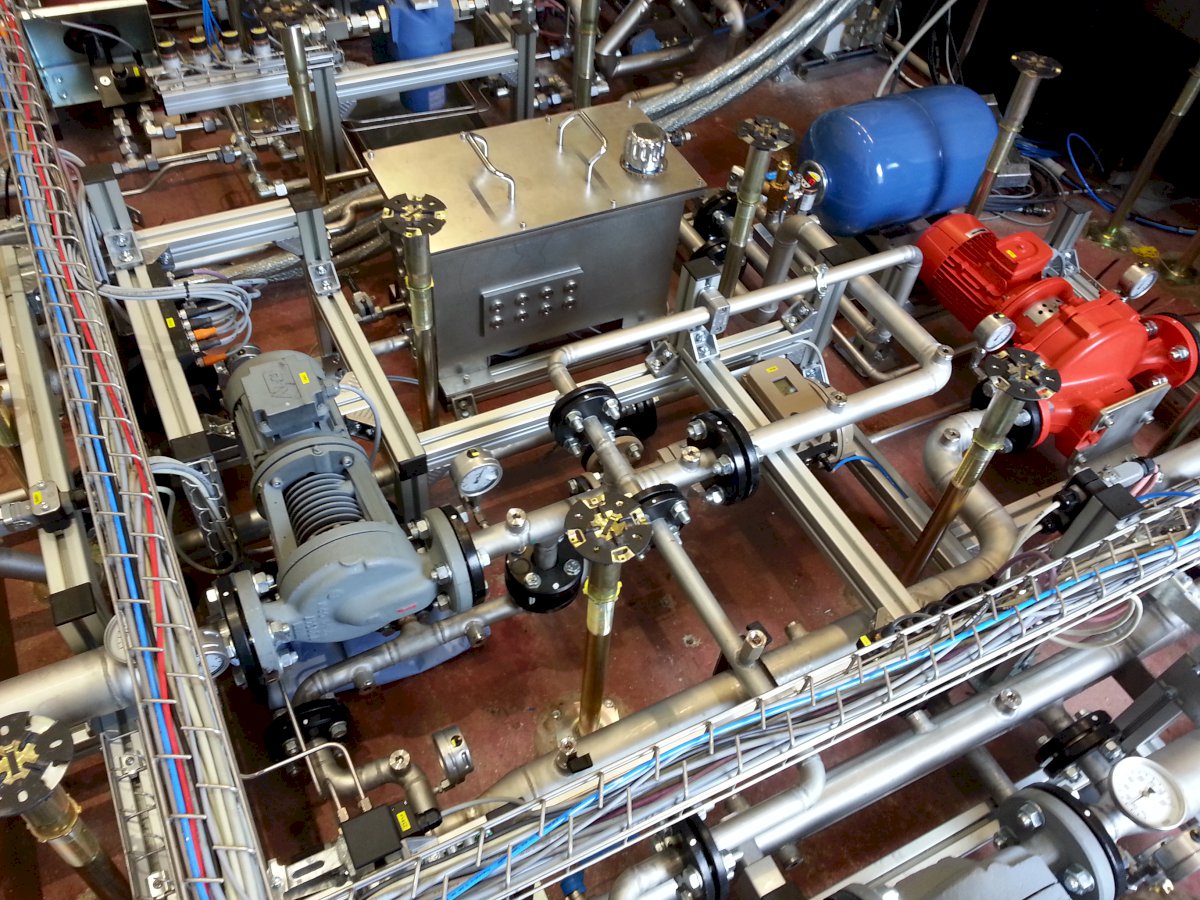

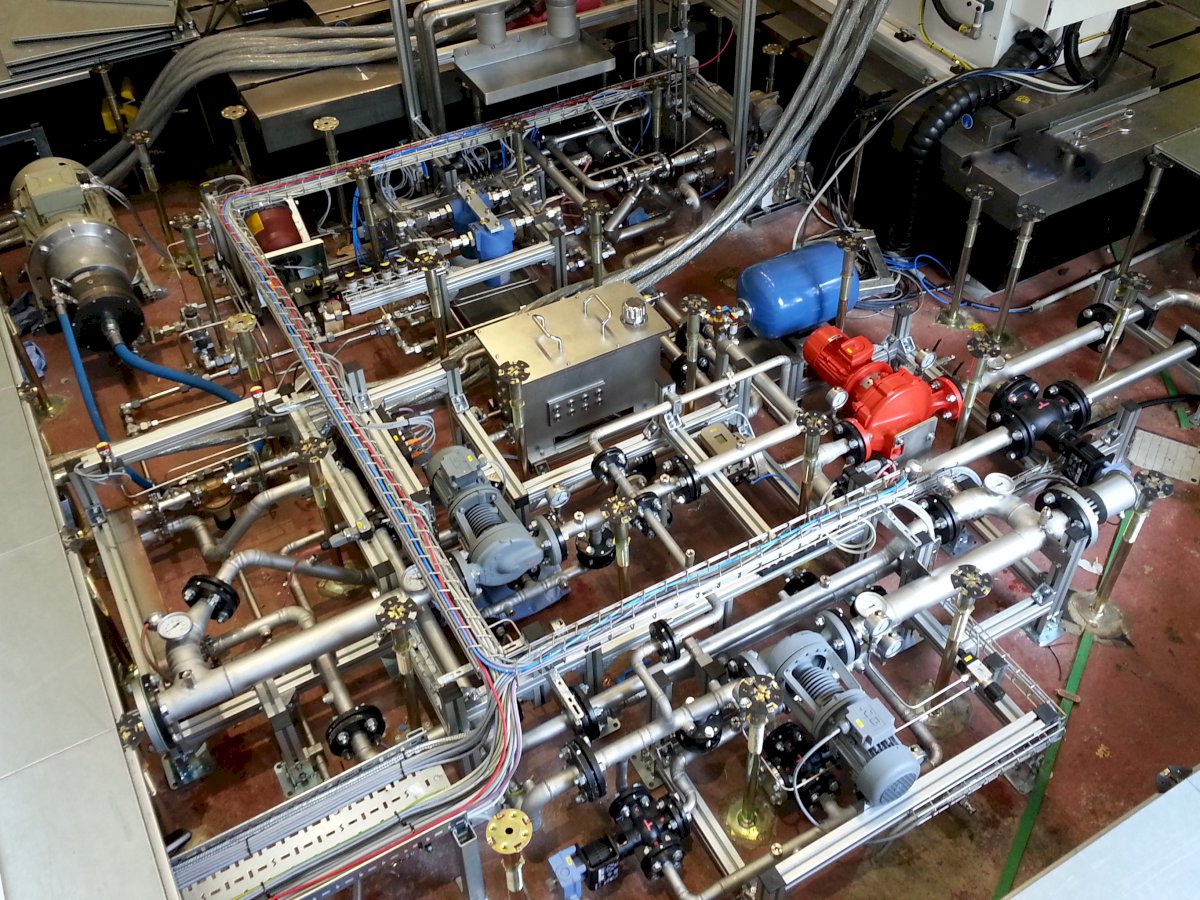

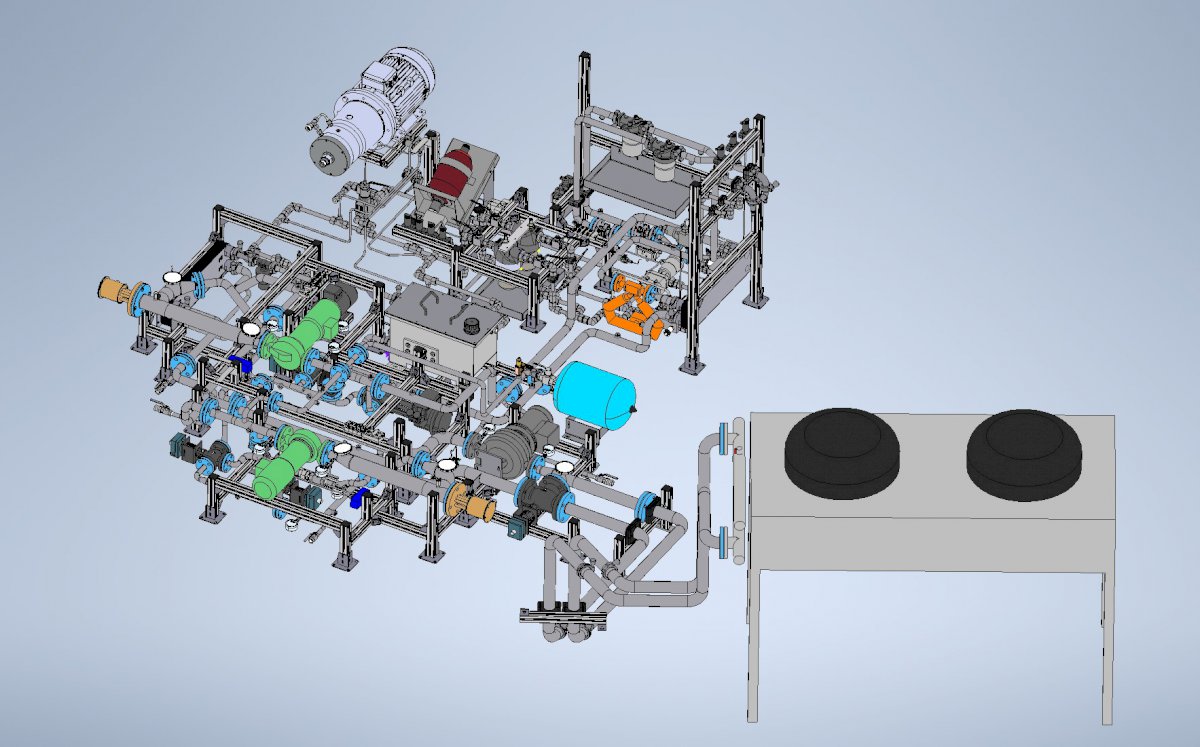

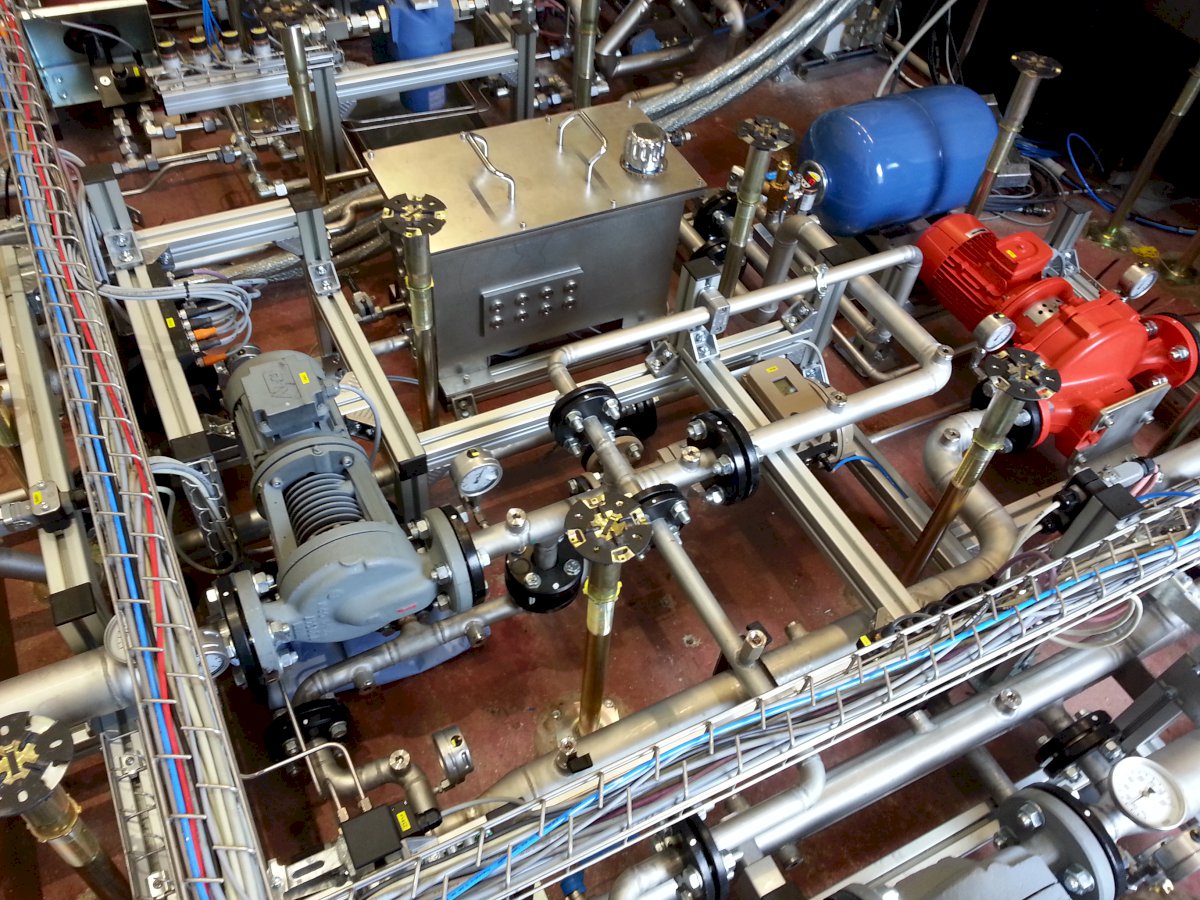

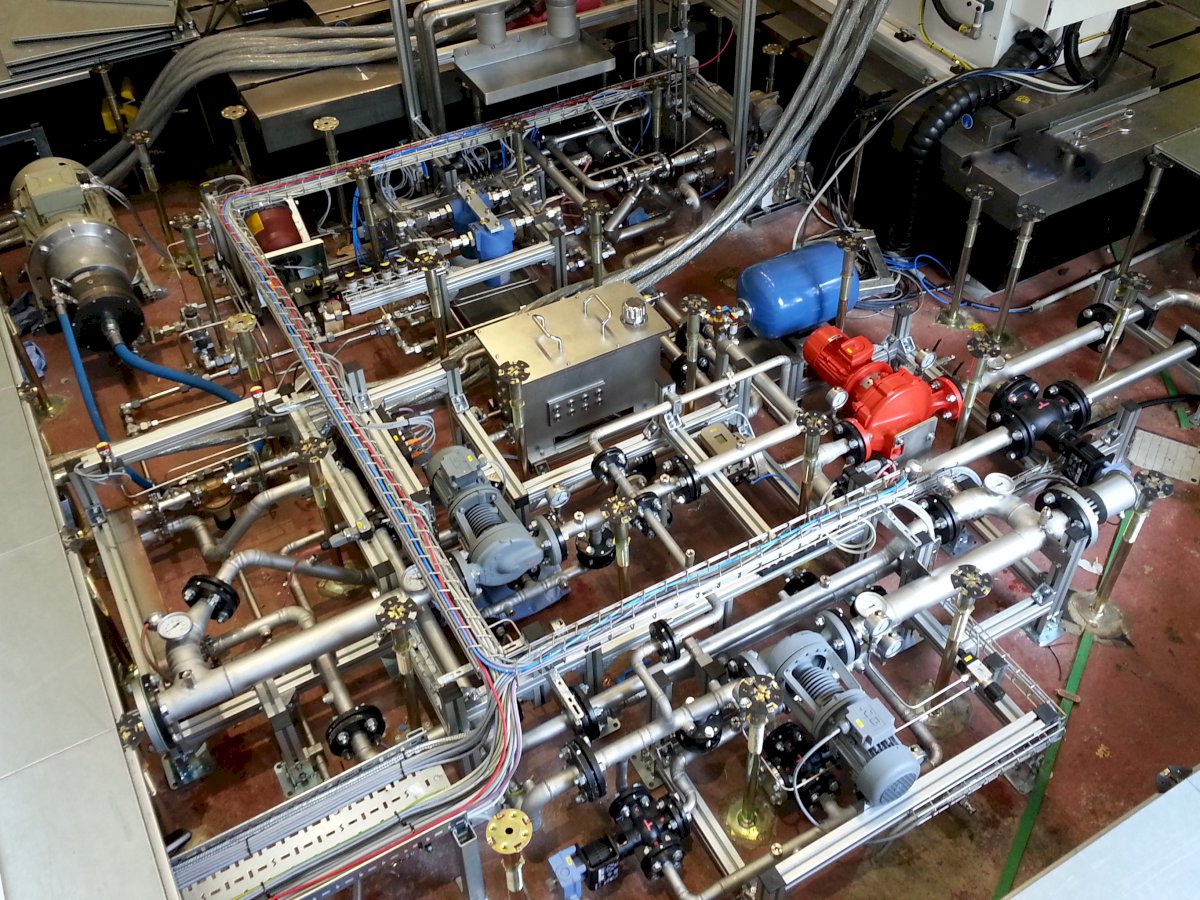

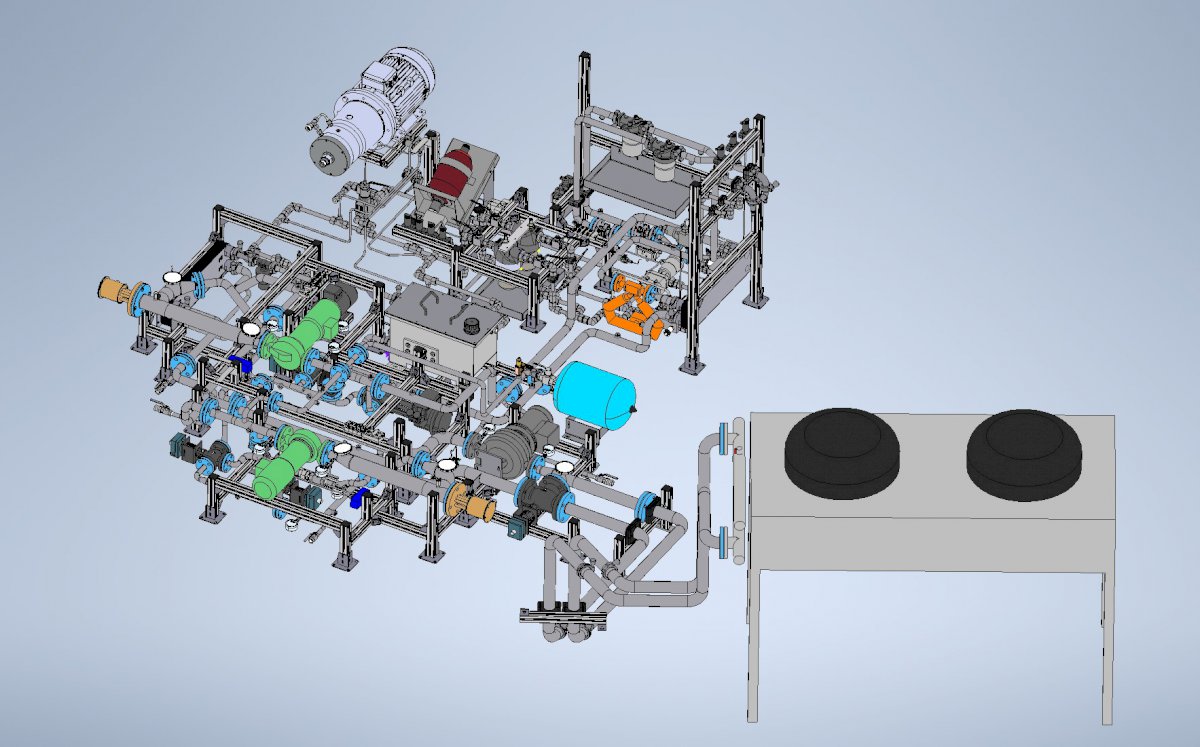

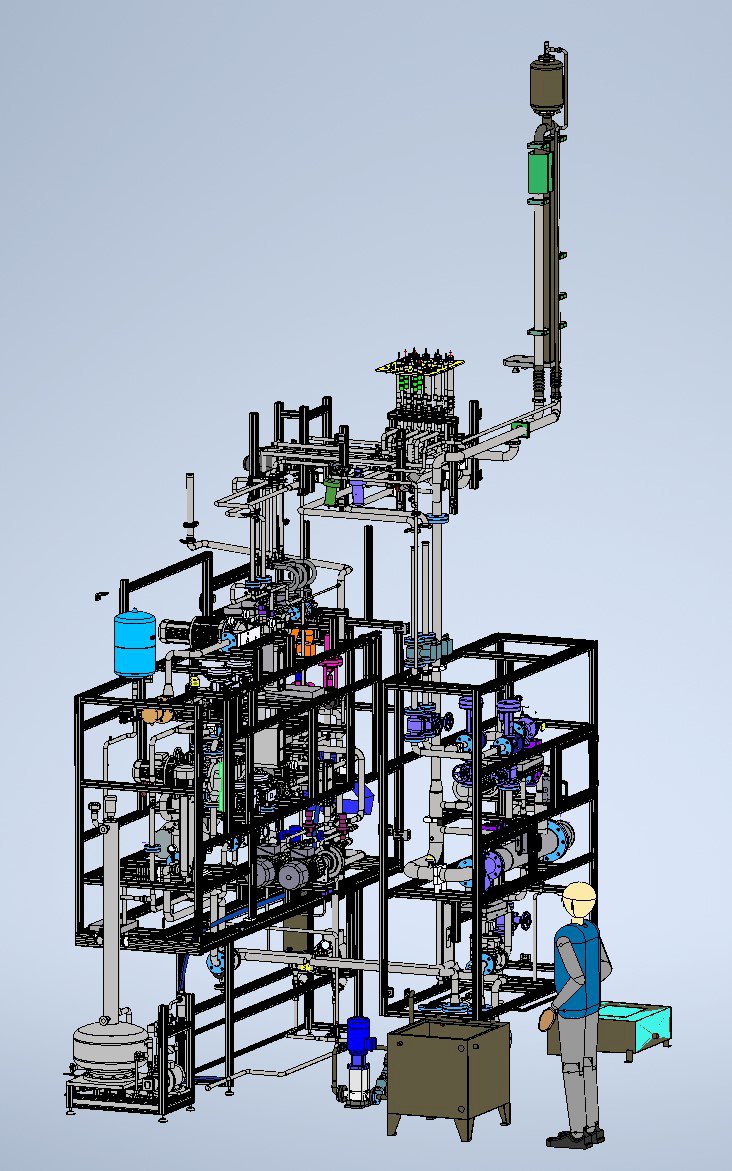

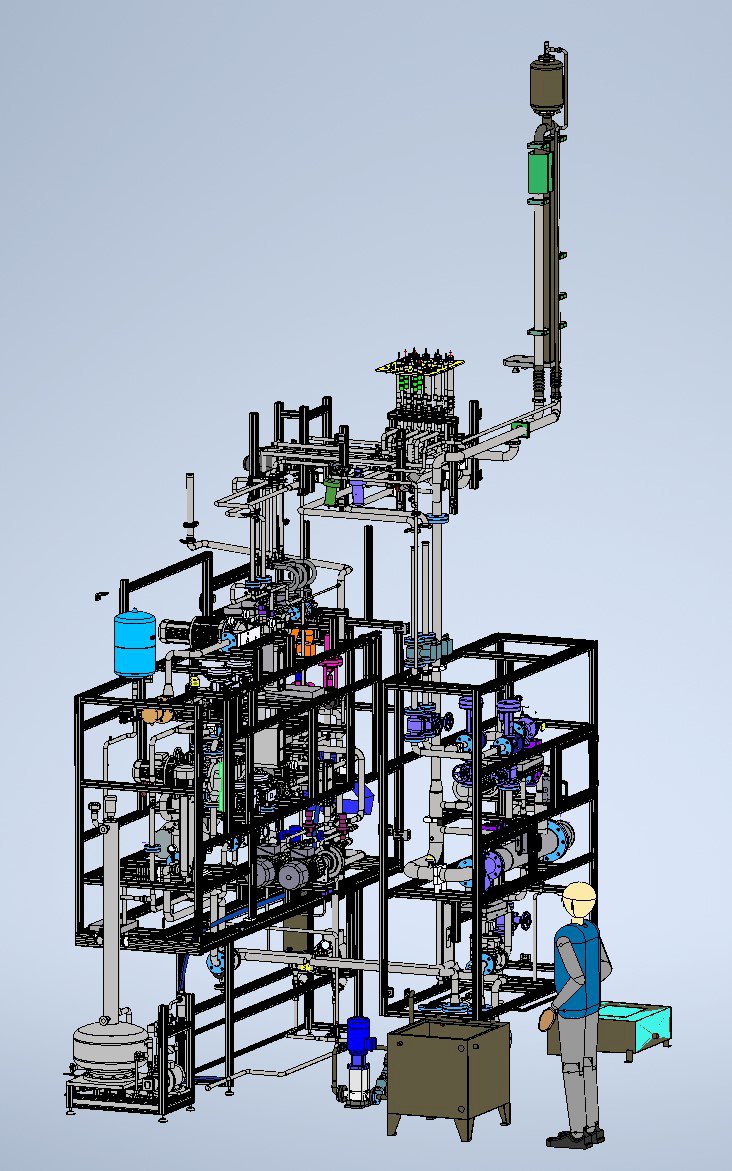

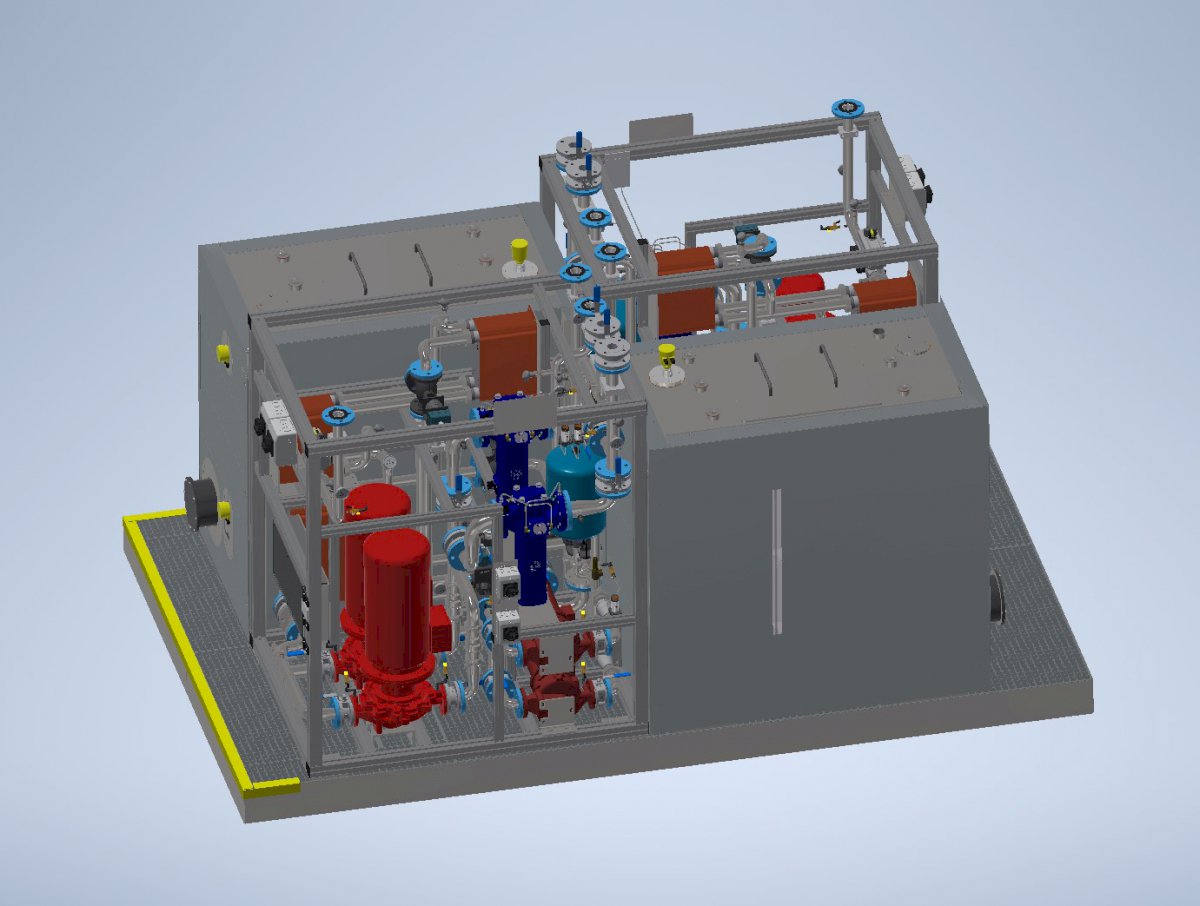

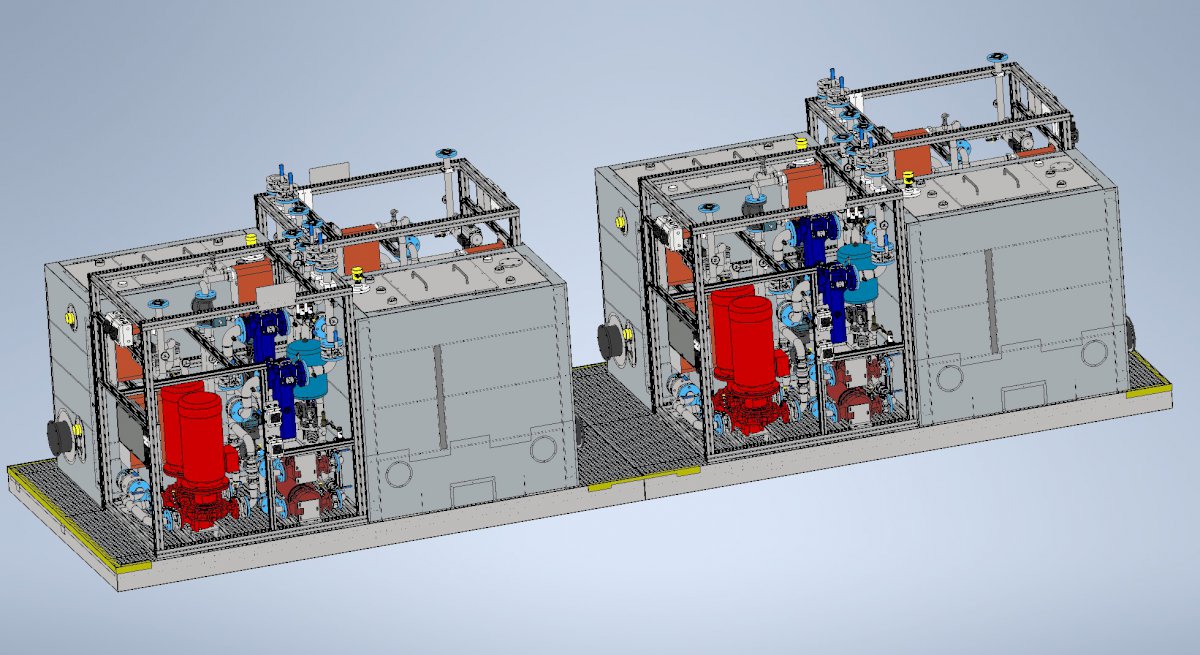

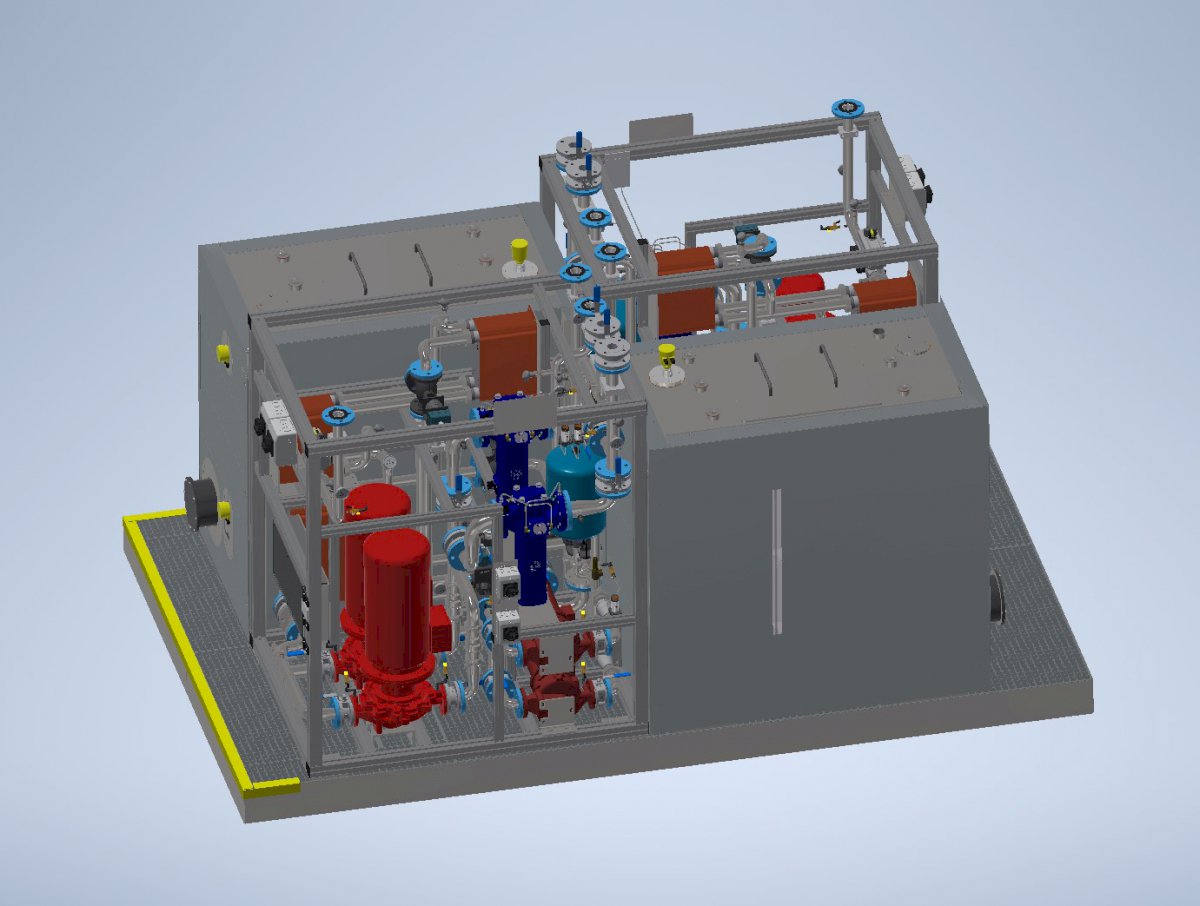

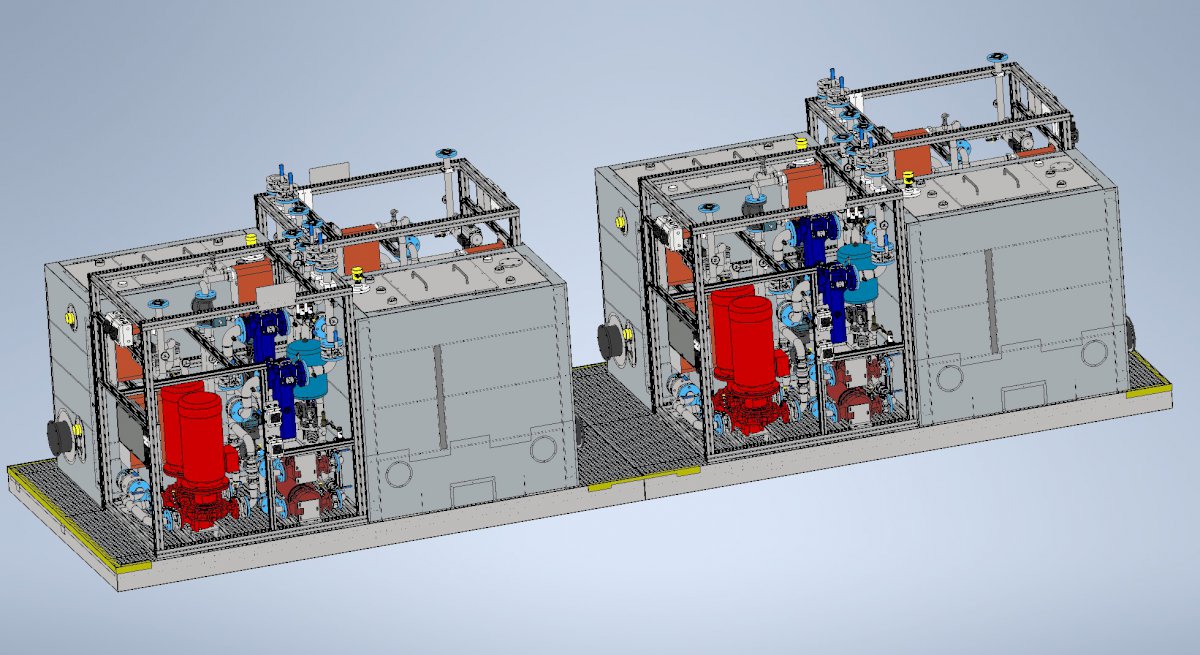

The conditioning unit is part of a test stand with wind tunnel for Formula 1 vehicles. The plant consists of a water system with two control circuits and an oil system with a single control circuit. Both circuits have a floor tank inside the test cell for filling and emptying the test specimens.

There is a second tank in the oil system that is constantly filled with medium. This is circulated continuously during operation and set to the corresponding temperature. Both the oil and water systems feature a heating unit with 200 kW of heating power.

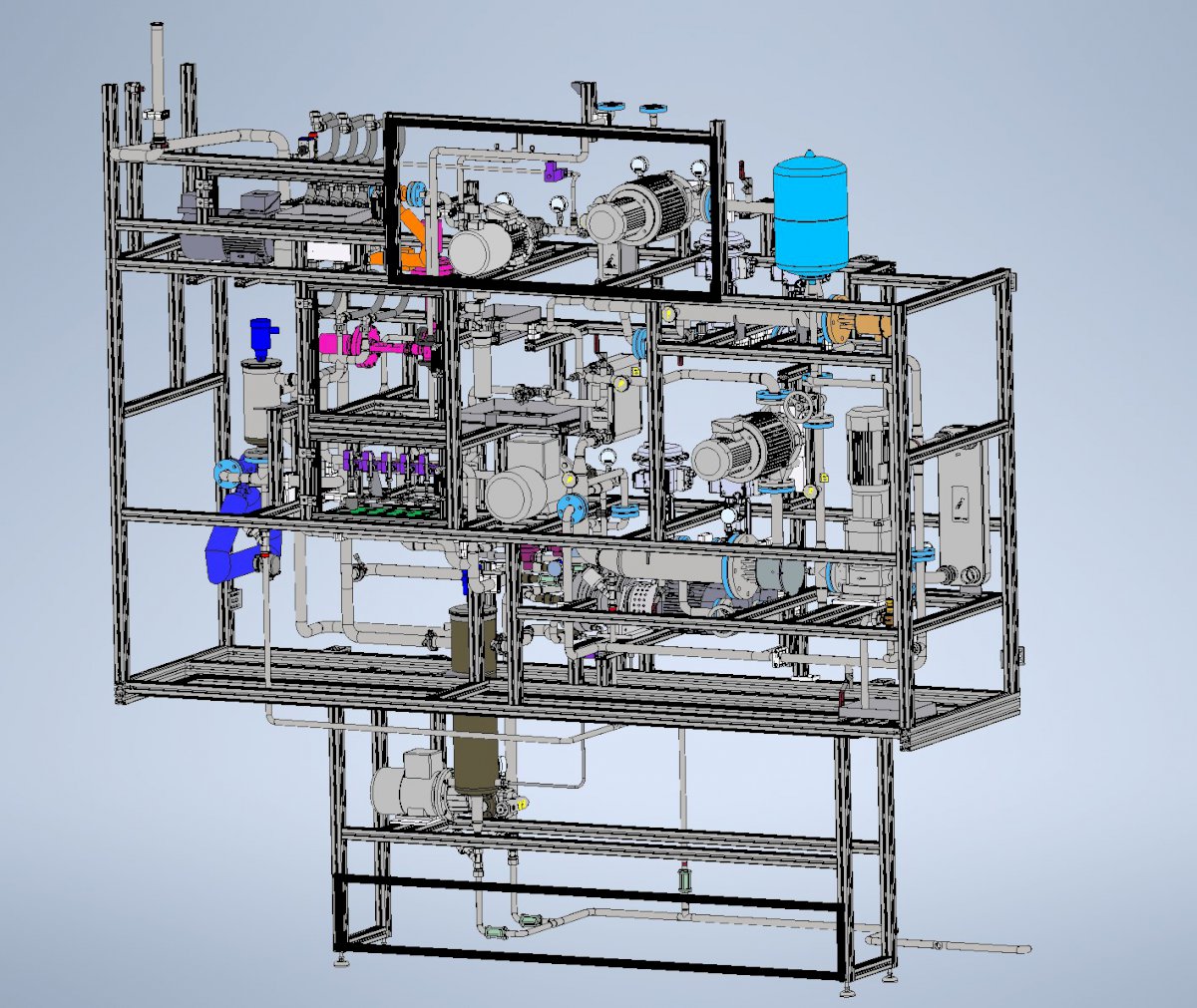

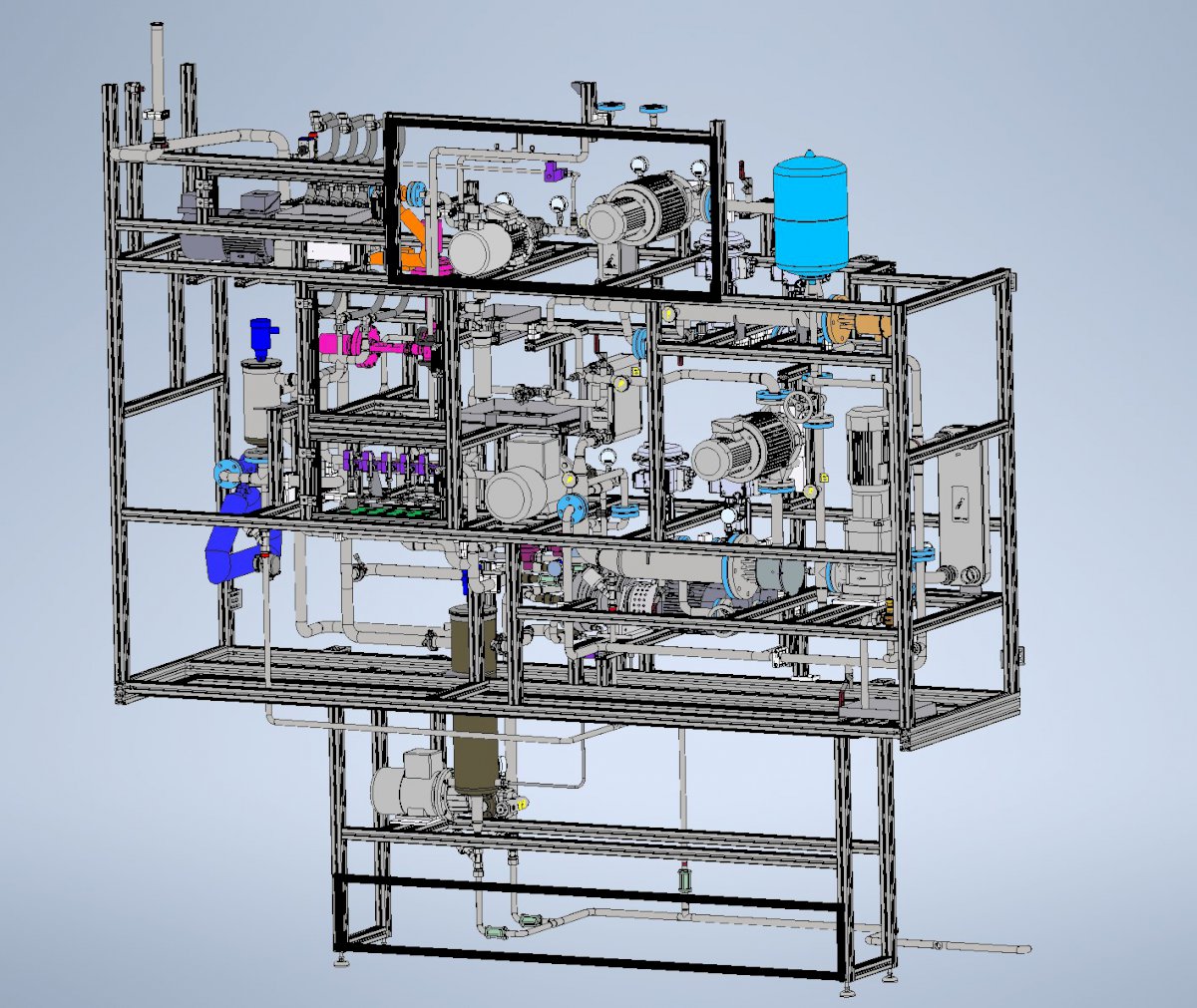

The conditioning system is part of a gearbox test stand. The oil and hydraulic oil are conditioned for tests, while the temperature and pressure of the media are set to specified parameters. The media is recooled via an air-water heat exchanger outside the building.

The conditioning system is used for highly dynamic conditioning of water and engine oil in various circuits for racetrack lap simulations.

Control variables:

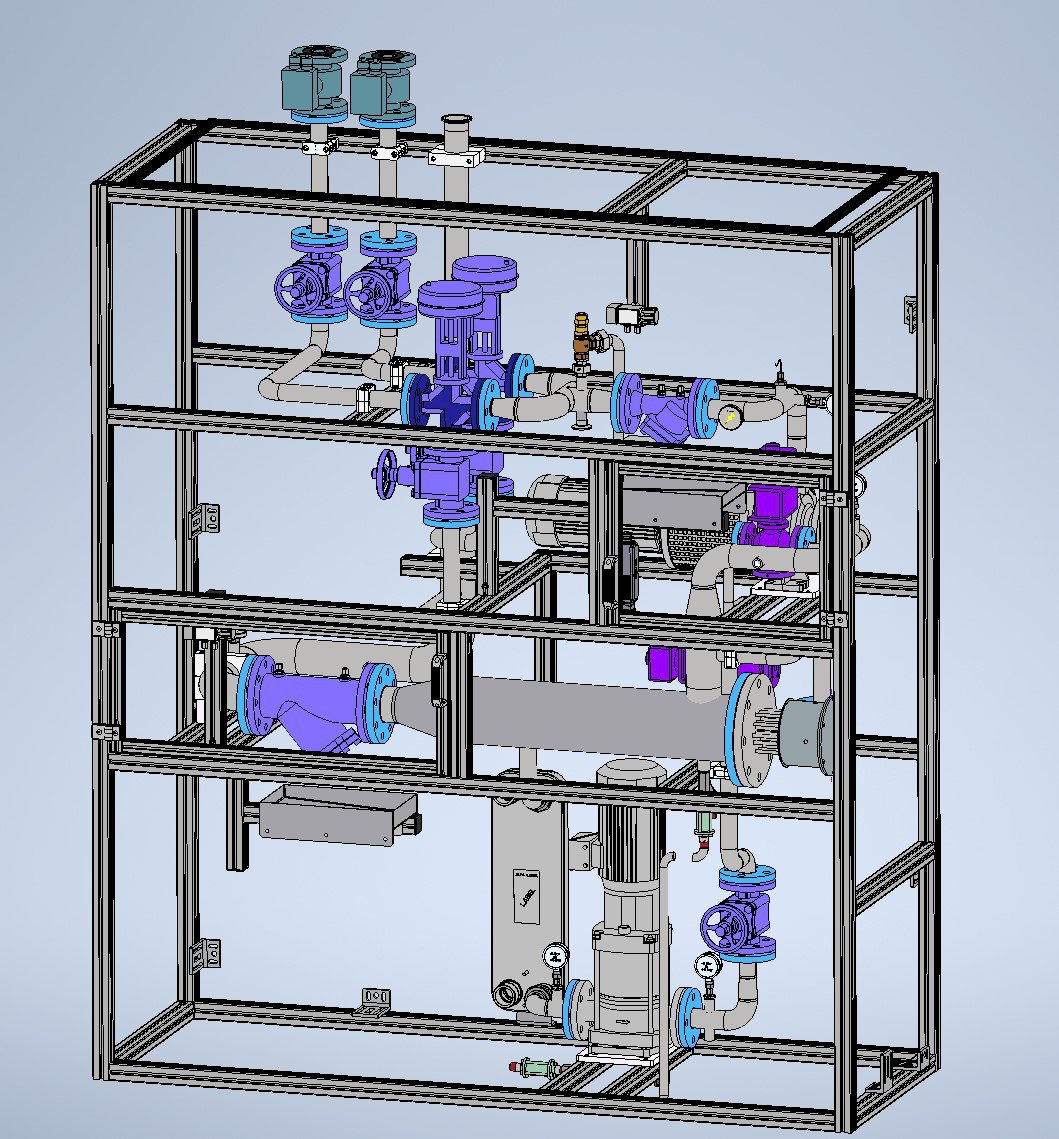

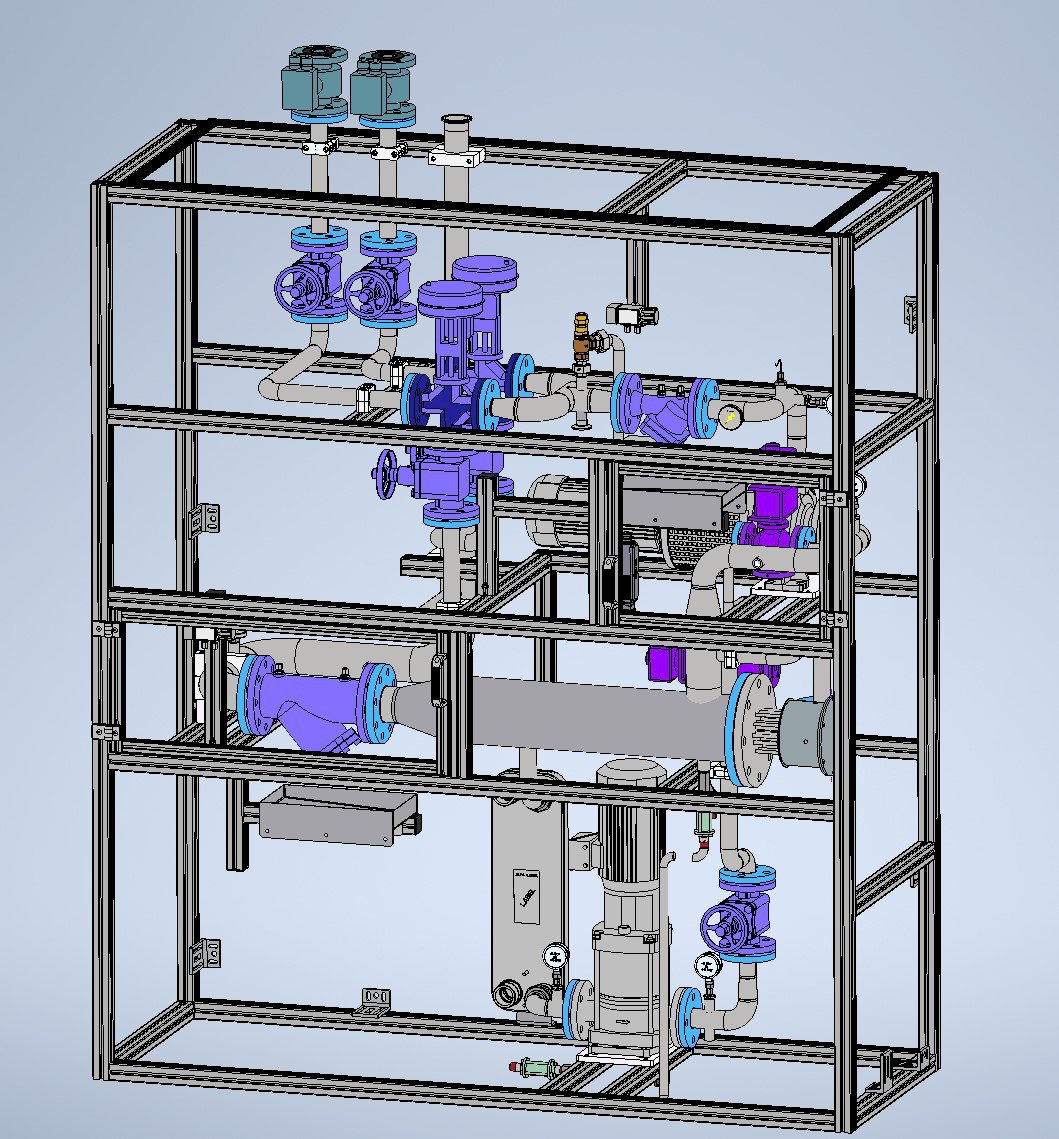

The oil conditioning system is connected to the engine test stands. It has four stations with a connected tank. A total of four ring circuits supply the 12 cold test stands with various types of oil.

The oil tank is refilled automatically once the fill level falls below the setpoint value. The refilled engine oil is heated to the required temperature via district heating and a pair of heat exchangers.