Design & development

- Designs based on specifications and on-site assessments, in line with the latest technical standards and EU directives

- Modular system planning, using standardised and purchased parts from leading manufacturers as much as possible

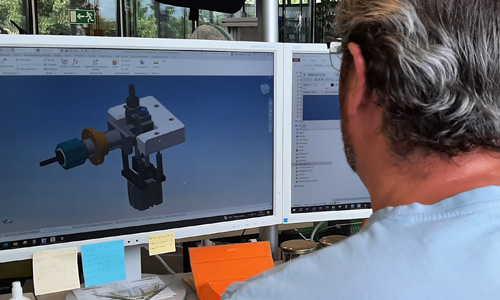

- Changes and expansions incorporated during the planning phase

- CAD workstations with various interfaces to the customer, compatible with all standard formats

Production

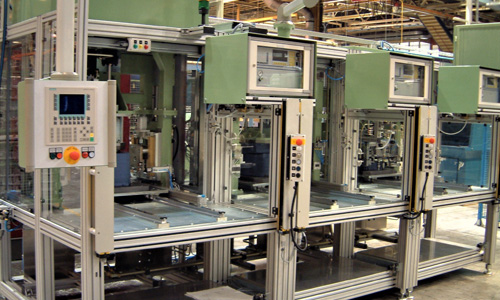

- Production of single systems, small series and complete lines

- One partner for all assembly services

- Strict quality control for individual parts and system testing before delivery

- Acceptance and machine capability verification together with customer

Commissioning and training

- LAIB stand-alone machines are all “plug and play”

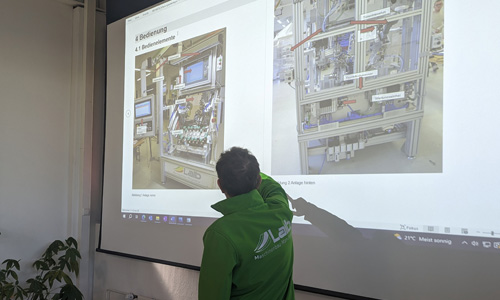

Training

- On-site training and expert instructors help customers work effectively with their machines

- Reliable support through to the smooth start of series production

Maintenance & spare parts

- 24-hour service if required, even on weekends and public holidays

- Remote maintenance and production monitoring

- Comprehensive stock of spare and purchased parts, short access times

Conversion and retrofitting

- Quick, uncomplicated conversions and adjustments for new workpieces

- LAIB converts existing machines for new tasks, further boosting investment security

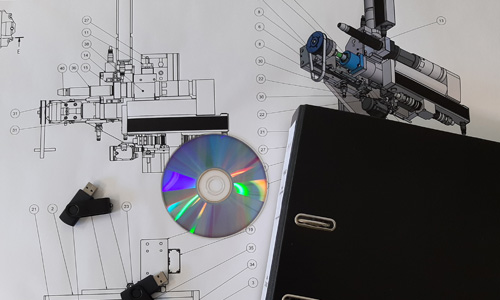

Documentation

- Detailed technical documentation in digital or paper form with CE declaration