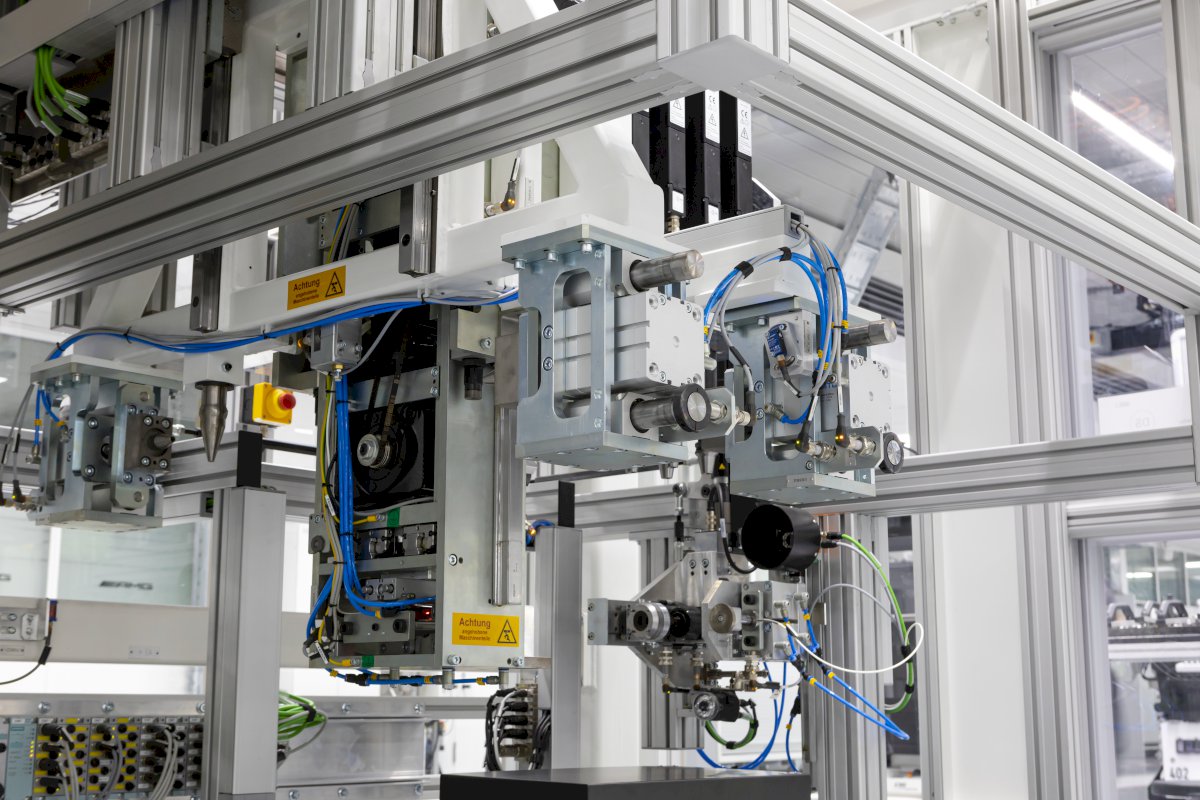

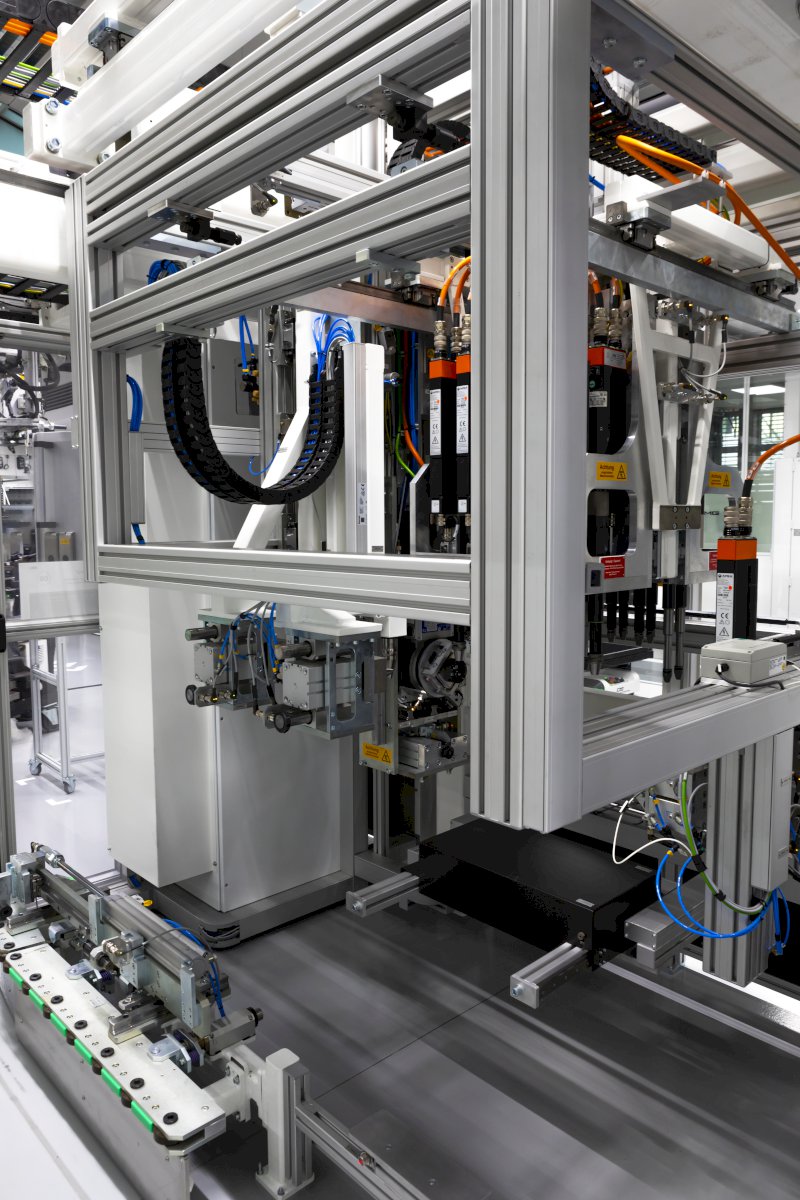

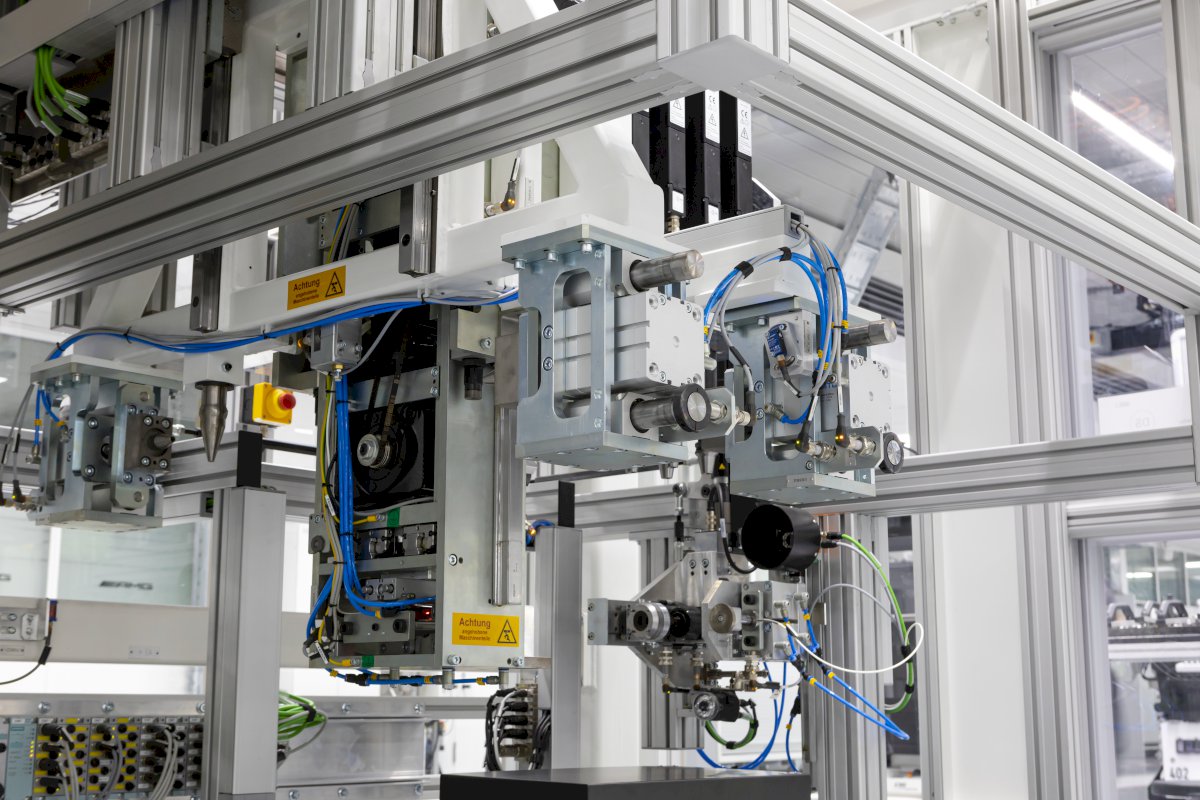

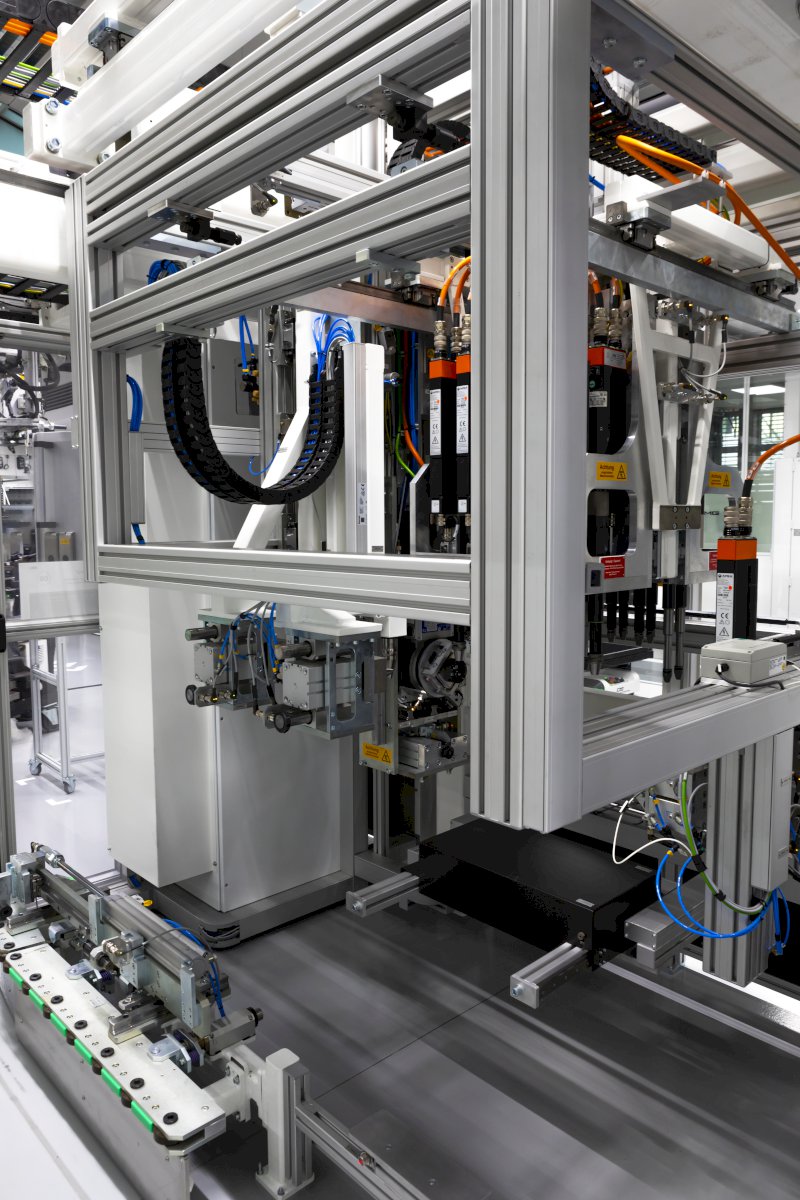

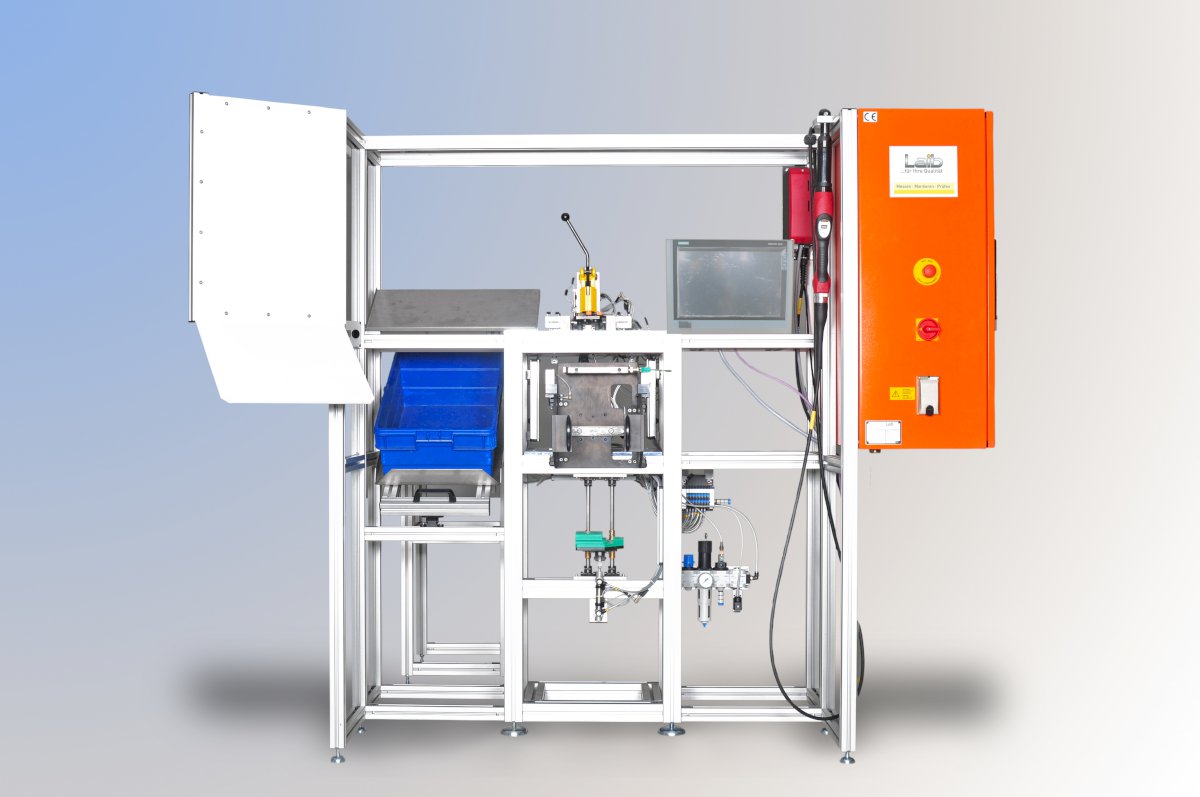

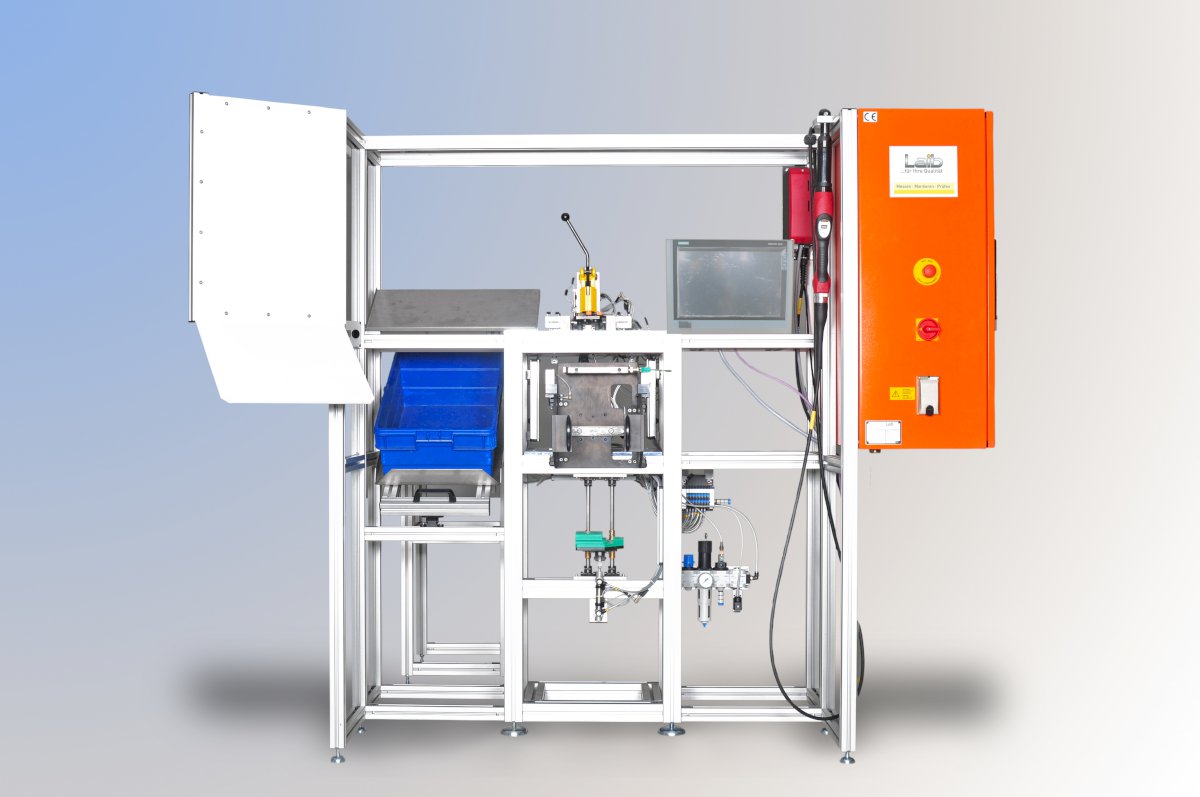

Assembly and testing station for vehicle engines in manual production

The engine is inserted into a fully automatic assembly and testing station on an assembly trolley. The following steps are then performed fully automatically:

- Reading of the DMC content for the pistons

- Checking of the pistons’ installation direction

- Checking for the water choke

- Checking for the water pump shaft

- Screwing on the main bearings

- Screwing on the big-end bearings

- Screwing on the oil pump wheel

- Axial play measurement on the crankshaft

- Breakaway torque

- Starting torque

- Rework modes for screwing and measuring